- Home

- About Us

- Products

- Applications

- Service & Support

- Videos

- News

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

ERM1325CBL ATC

Eastrise

Application of Atc Wood Working Cnc Router

Furniture industry: ideally suitable for processing cabinet door, wooden door, solid wood furniture, panel wood furniture, windows, tables and chairs, etc.

Decoration industry: screens, wave board, large wall hanging, advertising boards, sign making.

Artwork industry: solid wood, MDF, artificial stone, bamboo, marble, organic board, double-color board etc.

Advantage of Atc Wood Working Cnc Router

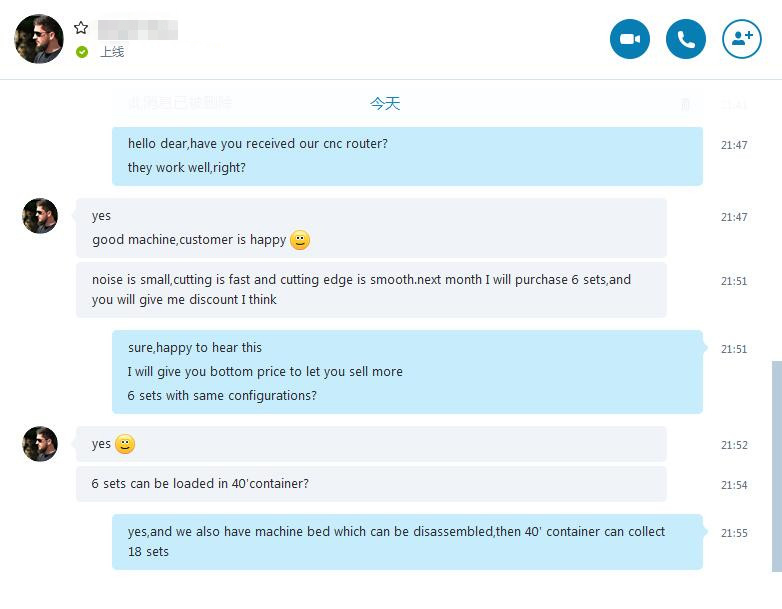

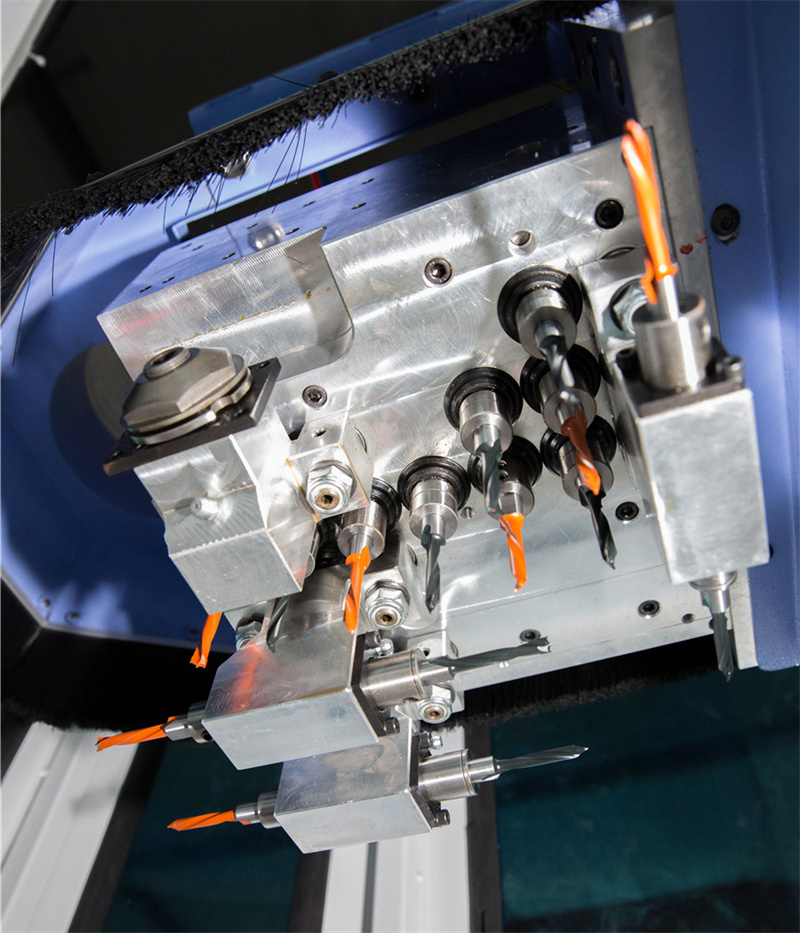

1. Italy Hiteco drilling bank(7V+2H).

Most famous brand of the world,high efficiency of boring ,many after service

Departments all over the world.

2. 9.0kw HSD air cooling spindle

Air cooling spindle with perfect cooling effect, long life and high stability with 24000RPM.HSD air cooling spindle is well known brand,high quality and big torque keep its longer lifetime up to 10years.

This processing center comes with a 9.0Kw air cooling spindle and 12pcs carousel automatic tool changer magazine. This precision spindle requires no maintenance, uses industry standard ER collets and ISO tool holders. Fully programmable speeds from 6000 to 24000 RPM, and comes complete with pneumatically retractable vacuum hood.

The 8pcs carousel ATC moves with the machine while the gantry travels. The use of a carousel speeds up tool changes assuring faster cycle times increasing production capability.

3.Machine structure

All frames are designed using state-of-the-art CAD/CAM software which analyze stresses applied to the frame’s structure, assures the support foundation is structurally stable that will last the test of time.

4.Each frame is stress relieved assuring long term stability in the frame structure mechanics.

The gantry is constructed of tubular steel with reinforcing ribs welded throughout the length of the column which results in a steady beam assembly. This quality engineering and workmanship result in smooth precision cutting.

The Gantry side plate are cast iron with heavy duty gussets formed into the casting. Each support is machined for housing the various drive assemblies including motors, bearings, and wiring harnesses.

5.The automatic loading system includes a lifter which supports and raises the stack of material to the machine's vacuum bed height, which is monitored with optical eye-sensing stack material height and machine bed surface.

6.Optical eye-sensing

When one piece of material is taken to process, then the lift will go up, but when up to the optical eye-sensing area, the lift will stop and keep the right location for next picking.

7.Suction Cup Load System

The rear suction cup load system attached to the processing center gantry can easily load a sheet on to the bed surface. As it loads, it automatically sweeps the deck clean of any debris assuring a clean scavenger board surface for maximum vacuum hold down as it processes each and every sheet.

8. Automatic loading auxiliary device

When the suction cup load a sheet, during their move process with the gantry, the auxiliary device will help to reduce resistance and more easier to travel.

9. Material Alignment System

The pop up side rails keep the previous routed nest uniform as the material is pushed onto the conveyor.

The loading and unloading process could occur at the same time.

After processing one sheet, then unloading system will push the materials to conveyor, meanwhile send another sheet to the processing table. And, during this process, the material alignment system will always work to make sure the material on the right location.

10. Belt conveyor unloading system

Conveyor table is located at the front end of the machine.

11. Control system

Taiwan Syntec control system 20MA + Hand wheel as your requirement

Technical parameters

Working area | 1300*2500*200mm |

Traveling speed | 70m/min |

Cutting speed | 25m/min |

Spindle parameters | 9.0kw air cooling spindle, 24000rpm |

Controller | Taiwan Syntec control system 20MA |

Driving | Japanese Yaskawa servo motor and drive 850W |

Working voltage | AC380v/3Ph/50Hz |

Electrical accessories | France Schneider low voltage components |

N.W./G.W. | 4200KG/4500KG |

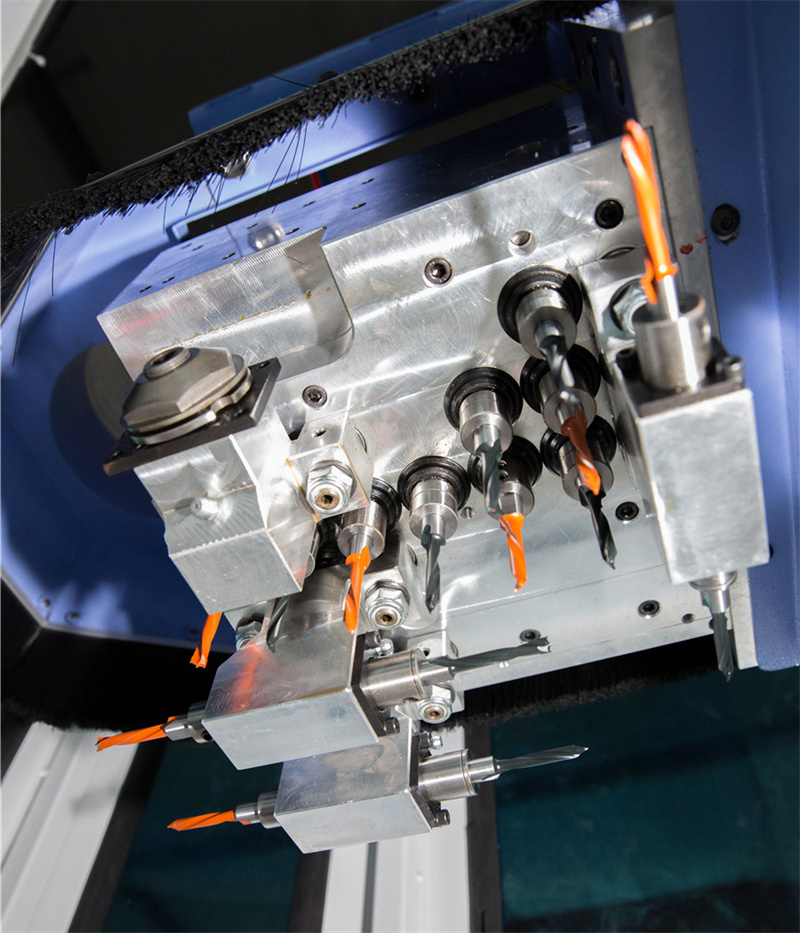

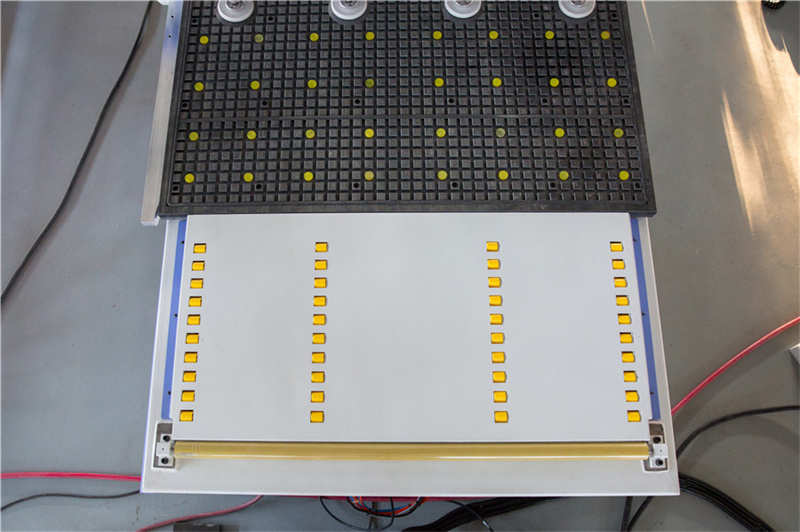

Table structure | Double-deck of Multi-point high vacuum adsorbable countertop |

Machining

Testing

Certificate

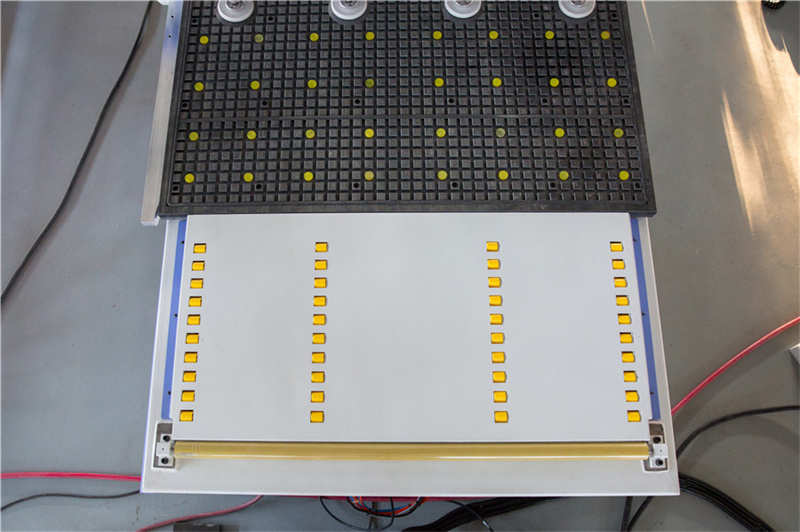

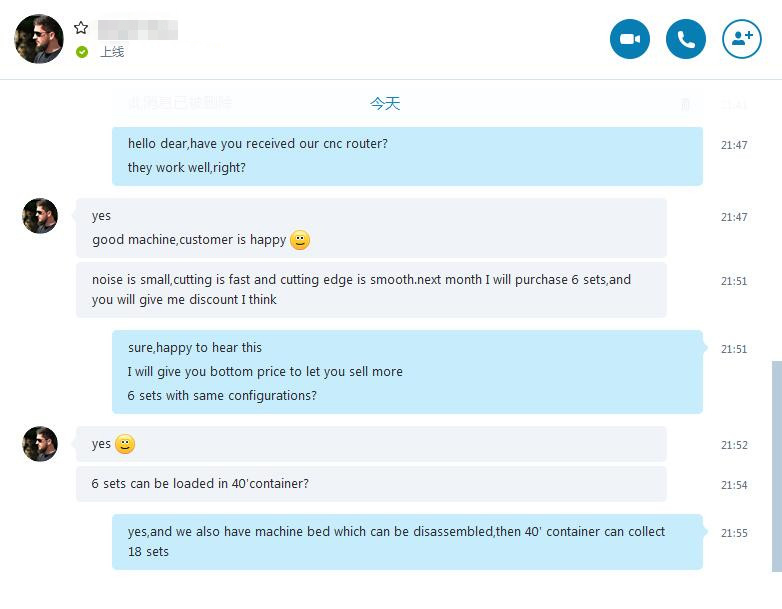

Feedback from customer

Application of Atc Wood Working Cnc Router

Furniture industry: ideally suitable for processing cabinet door, wooden door, solid wood furniture, panel wood furniture, windows, tables and chairs, etc.

Decoration industry: screens, wave board, large wall hanging, advertising boards, sign making.

Artwork industry: solid wood, MDF, artificial stone, bamboo, marble, organic board, double-color board etc.

Advantage of Atc Wood Working Cnc Router

1. Italy Hiteco drilling bank(7V+2H).

Most famous brand of the world,high efficiency of boring ,many after service

Departments all over the world.

2. 9.0kw HSD air cooling spindle

Air cooling spindle with perfect cooling effect, long life and high stability with 24000RPM.HSD air cooling spindle is well known brand,high quality and big torque keep its longer lifetime up to 10years.

This processing center comes with a 9.0Kw air cooling spindle and 12pcs carousel automatic tool changer magazine. This precision spindle requires no maintenance, uses industry standard ER collets and ISO tool holders. Fully programmable speeds from 6000 to 24000 RPM, and comes complete with pneumatically retractable vacuum hood.

The 8pcs carousel ATC moves with the machine while the gantry travels. The use of a carousel speeds up tool changes assuring faster cycle times increasing production capability.

3.Machine structure

All frames are designed using state-of-the-art CAD/CAM software which analyze stresses applied to the frame’s structure, assures the support foundation is structurally stable that will last the test of time.

4.Each frame is stress relieved assuring long term stability in the frame structure mechanics.

The gantry is constructed of tubular steel with reinforcing ribs welded throughout the length of the column which results in a steady beam assembly. This quality engineering and workmanship result in smooth precision cutting.

The Gantry side plate are cast iron with heavy duty gussets formed into the casting. Each support is machined for housing the various drive assemblies including motors, bearings, and wiring harnesses.

5.The automatic loading system includes a lifter which supports and raises the stack of material to the machine's vacuum bed height, which is monitored with optical eye-sensing stack material height and machine bed surface.

6.Optical eye-sensing

When one piece of material is taken to process, then the lift will go up, but when up to the optical eye-sensing area, the lift will stop and keep the right location for next picking.

7.Suction Cup Load System

The rear suction cup load system attached to the processing center gantry can easily load a sheet on to the bed surface. As it loads, it automatically sweeps the deck clean of any debris assuring a clean scavenger board surface for maximum vacuum hold down as it processes each and every sheet.

8. Automatic loading auxiliary device

When the suction cup load a sheet, during their move process with the gantry, the auxiliary device will help to reduce resistance and more easier to travel.

9. Material Alignment System

The pop up side rails keep the previous routed nest uniform as the material is pushed onto the conveyor.

The loading and unloading process could occur at the same time.

After processing one sheet, then unloading system will push the materials to conveyor, meanwhile send another sheet to the processing table. And, during this process, the material alignment system will always work to make sure the material on the right location.

10. Belt conveyor unloading system

Conveyor table is located at the front end of the machine.

11. Control system

Taiwan Syntec control system 20MA + Hand wheel as your requirement

Technical parameters

Working area | 1300*2500*200mm |

Traveling speed | 70m/min |

Cutting speed | 25m/min |

Spindle parameters | 9.0kw air cooling spindle, 24000rpm |

Controller | Taiwan Syntec control system 20MA |

Driving | Japanese Yaskawa servo motor and drive 850W |

Working voltage | AC380v/3Ph/50Hz |

Electrical accessories | France Schneider low voltage components |

N.W./G.W. | 4200KG/4500KG |

Table structure | Double-deck of Multi-point high vacuum adsorbable countertop |

Machining

Testing

Certificate

Feedback from customer