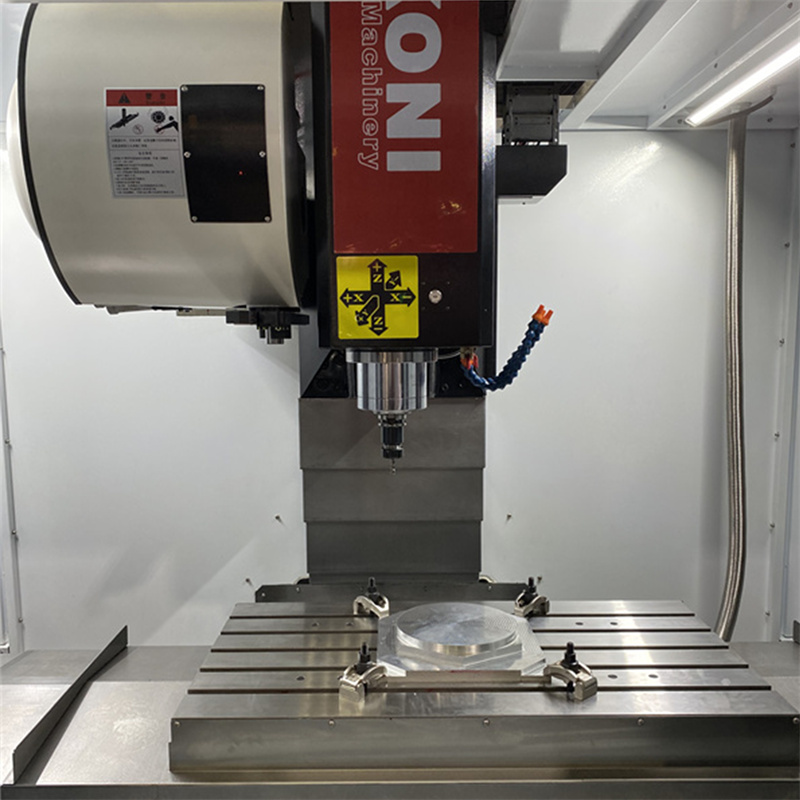

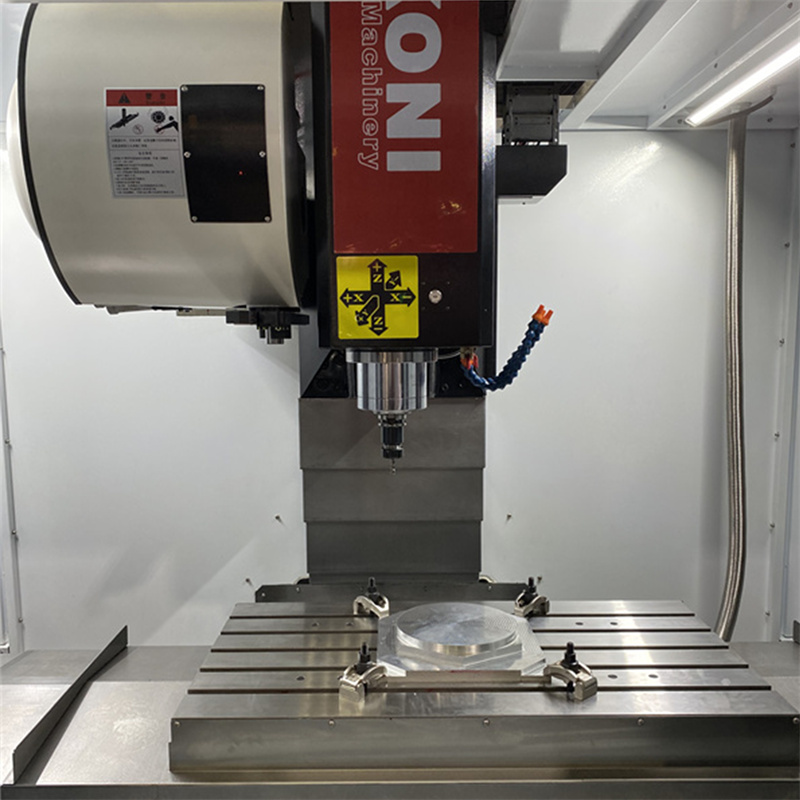

Automatic Cnc Machining Center MKN-855V

CNC machining centers are high-efficiency automated machine tools suitable for machining complex parts, which are composed of mechanical equipment and CNC systems. CNC machining center is currently the world's highest yield, one of the most widely used CNC machine tools. Its comprehensive processing capability is stronger, the workpiece can be completed after a clamping more processing content, processing accuracy is higher, on the medium processing difficulty of the batch of workpieces, its efficiency is 5 to 10 times the ordinary equipment, especially it can complete many ordinary equipment can not be completed processing, the shape of the more complex, high precision requirements of the single piece of machining or small and medium batches of multi-species production is more suitable.

CNC machining center is a more full-featured CNC machining machine. It concentrates the functions of milling, boring, drilling, tapping and cutting threads in a single device, making it a variety of process means. The machining center is set up with a tool magazine, in which different numbers of various tools or checking tools are stored, which are automatically selected and replaced by the

program during the machining process. This is the main difference between it and CNC milling machine, CNC boring machine. Especially for the necessity of using tooling and specialized equipment to ensure product quality and efficiency of the workpiece. This will save a lot of time and cost for the development of new products and modeling replacement, so that the enterprise has a strong competitive ability.

Features of CNC machining centers

Machining centers are high-efficiency, high-precision CNC machine tools, the workpiece in a clamping can be completed in a multi-process processing, but also has a tool library, and automatic tool change function. Machining centers have these rich features, determines the complexity of machining center programming.

Machining centers can achieve three or more than three-axis linkage control to ensure that the tool for complex surface machining. Machining centers in addition to linear interpolation and circular arc interpolation function, but also has a variety of machining fixed cycle, automatic tool radius compensation, automatic tool length compensation, graphic display of the machining process, man-machine dialogue, automatic fault diagnosis, offline programming and other functions.

Advantages of CNC machining centers

①The number of fixtures is greatly reduced, and complex fixtures are not required for processing parts with complex shapes. If you want to change the shape and size of the parts, you only need to modify the parts processing program, suitable for new product development and retrofit.

② stable processing quality, high processing accuracy, high repeatability, adapted to the processing requirements of the aircraft.

③ Higher production efficiency in the case of multi-species, small batch production, can reduce the time of production preparation, machine tool adjustment and process inspection, and due to the use of the optimal amount of cutting and reduce the cutting time.

④Can process complex surfaces that are difficult to process by conventional methods, and can even process some unobservable machining parts.

CNC Machining Center Applications

CNC Machining center parameters

| Model | MKN-855V |

| Table Size | 1000*550mm |

| Working Area (X/Y/Z Axis) | 800*550*550mm |

| Position accuracy | ±0.005mm |

| Repeat Positioning Accuracy | ±0.003mm |

| X/Y/Z axis rapid feed | 48/48/48m/min |

| Cutting feeds | 20000mm/min |

| Max Loading Weight | 500KG |

| Spindle Power | 7.5KW(Optional 11KW) |

| Tool holder | BT40 |

| Tool capacity | 24T |

| Fast tool change time | 2sec |

| Spindle rotate speed | 10000rpm |

| Power supply | 380V ± 10%50Hz |

| Machine weight | 5000KG |

English

English