MIKONI Carving And Milling Machine 540P-DX

Carving and milling machine, both accurate engraving and milling. It is an efficient and highly precise CNC machine tool. The carving and milling machine drives the tool through the high-speed rotating spindle to precisely engrave and mill the workpiece. It is capable of high-speed engraving, milling, drilling, cutting and other operations, and it is usually equipped with an advanced control system and precise mechanical structure to realize high-precision processing. During the working process, the carving and milling machine will automatically adjust the movement trajectory and cutting speed of the tool according to the preset program and parameters, so as to complete the processing tasks of various complex shapes and tiny sizes.

Features and advantages of carving and milling machine

1. High precision: the carving and milling machine has extremely high processing precision, which can meet the requirements of various complex shapes and tiny sizes.

2. High efficiency: due to the high spindle speed and high power of servo motor of the carving and milling machine, the processing speed is fast, which can significantly improve the production efficiency.

3. Good stability: the carving and milling machine has a reasonable design and solid structure, which can maintain stable operation in a long time of work.

4. Simple operation: the carving and milling machine adopts advanced numerical control technology, the operation is simple and convenient, easy to master.

5.Wide range of application: the carving and milling machine can be used for processing aluminum alloy, brass, copper, steel, iron, zinc alloy, magnesium alloy, gold, silver, molybdenum, acrylic, plastics, ceramics, carbon fiber, graphite plate and other materials.

Application areas of carving and milling machine

Carving and milling machine has a wide range of applications in the manufacturing industry, artwork creation and other fields. Specifically, it can be used for processing in the manufacturing industry (e.g., cell phone parts, electronic appliances, smart home), as well as for mold processing, automotive parts processing, and aerospace parts processing. In addition the engraving and milling machine can also be used in the field of handicraft engraving, stone engraving, etc., providing artists and craftsmen with more efficient and precise processing tools.

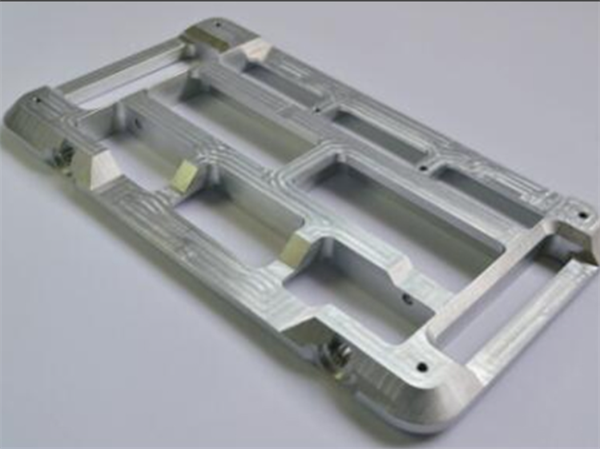

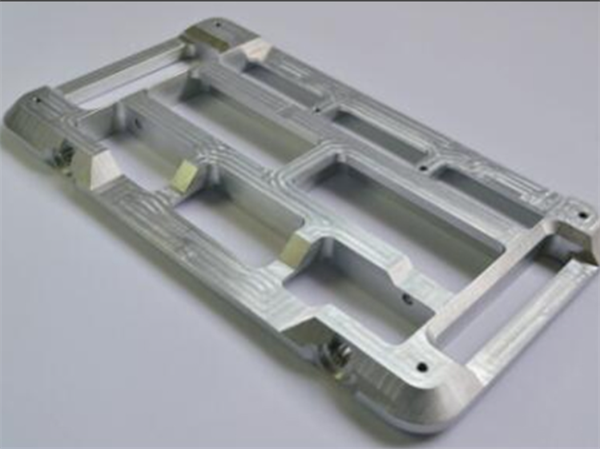

Precision Hardware Parts Processing

Traditional Mold Processing

ECU housing processing

High-end jade carving

Parameters of carving and milling machine

| Model | 540P-DX |

| Safe travel (X/Y/Z Axis) | 500/400/280mm |

| Position accuracy | 0.008/300mm |

| Repeat Positioning Accuracy | ≤0.005mm |

| Maximum movement speed | 15m/min |

| Maximum cutting speed | 10m/min |

| Max Loading Weight | 150KG |

| Spindle Power | 5.5KW (Optional 8.5KW) |

| Tool holder | BT30 |

| Tool capacity | 8T |

| Spindle rotate speed | 30000rpm |

| Control system | Syntec |

| Power supply | 380V ± 10%50Hz |

| Machine weight | 2100KG |

English

English