The detailed distinction between fiber laser cutting machine and plasma cutting machine

Views: 2 Author: Site Editor Publish Time: 2022-08-22 Origin: Site

1. Compared with plasma cutting, laser cutting is much more precise, the heat affected zone is much smaller, and the kerf is much smaller;

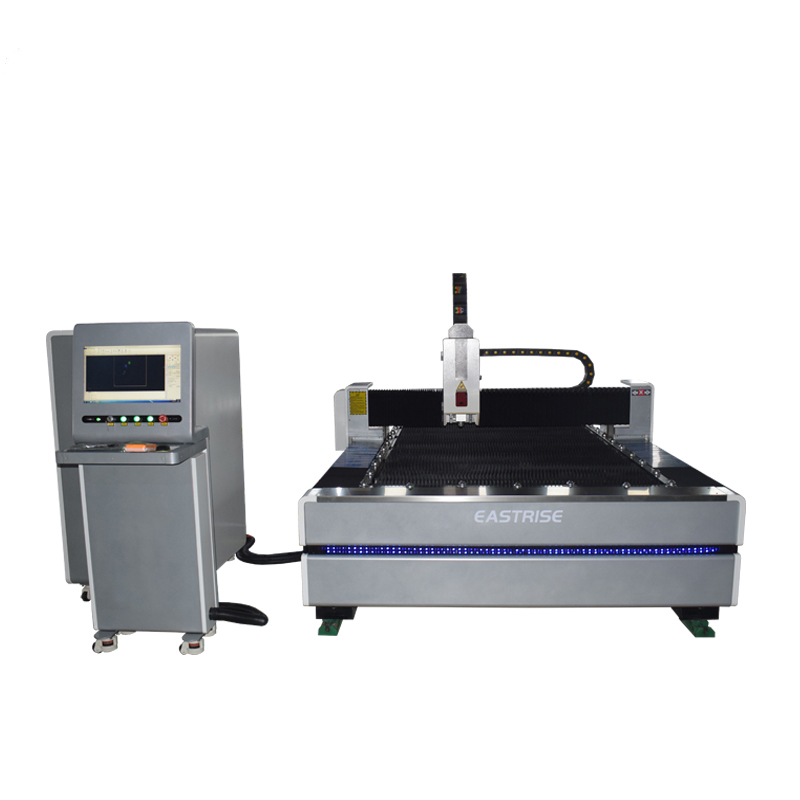

2. If you want precise cutting, small cutting seam, small heat-affected zone, and small deformation of the plate, it is recommended to choose

a laser cutting machine;

3. Plasma cutting uses compressed air as working gas, high temperature and high speed plasma arc as heat source, partially melts the metal to

be cut, and at the same time blows away the melted metal with high-speed airflow to form cutting;

4. The heat-affected zone of plasma cutting is relatively large and the slit is relatively wide, which is not suitable for cutting thin plates,

because the plates will be deformed due to heat.

English

English