Features of 2000*4000mm Big Size 2040 4-axis Polystyrene Cnc Router

1) Reliable and durable: all the machine parts have guaranteed quality, for example, Taiwan Syntec control system, HSD air cooling spindle, Taiwan Hiwin linear rails, Becker Vacuum pump, Taiwan Delta inverter and Taiwan TBI ball screw etc, to keep the machine in best condition even after working for many years.

2) Long-time working time with high precision and high efficiency: Welded square tube structure, anti-deformation, strong and relaible; Imported high-precision ball screw; High-performance driven motor; Working with dust hood on all three axis, which can stop dust away from the rails and ball screws, and to keep the machine working for longer time.

3) Humanized and beautiful designing: with attractive color and curvings in cosideration of convenient user operation at the same time.

4) Safe and high efficiency: Double limit protection in avoid of excessive machining; Unique preservation way of the zero point. Breakpoint specific memory to keep the carving status when power off, processing time forecast and other functions in case of the accidental power outages.

5) Easy operation and low maintenance cost. Perfect design and top quality accessories to minimize the machine’s failure rate

6) Many optional configuration and OEM service available.

Applicable materails

Part of polystyrene foam, plastic, wood materials, PVC, acrylic and other materials.

Features of 2000*4000mm Big Size 2040 4-axis Polystyrene Cnc Router

1. HSD spindle: original famous brand from Italian, you also can choose Hitech spindle.

2. SYNTEC control system: from Taiwan with high performance and competitive price.

3. Yaskawa servo motor and drives: from Japan with high precision and long life.

4. HIWIN linear guide: from Taiwan, it is used for linear reciprocating stadium.

5. Working area: 2000*4000*1200mm, C Rotary Axis: 180 degree.

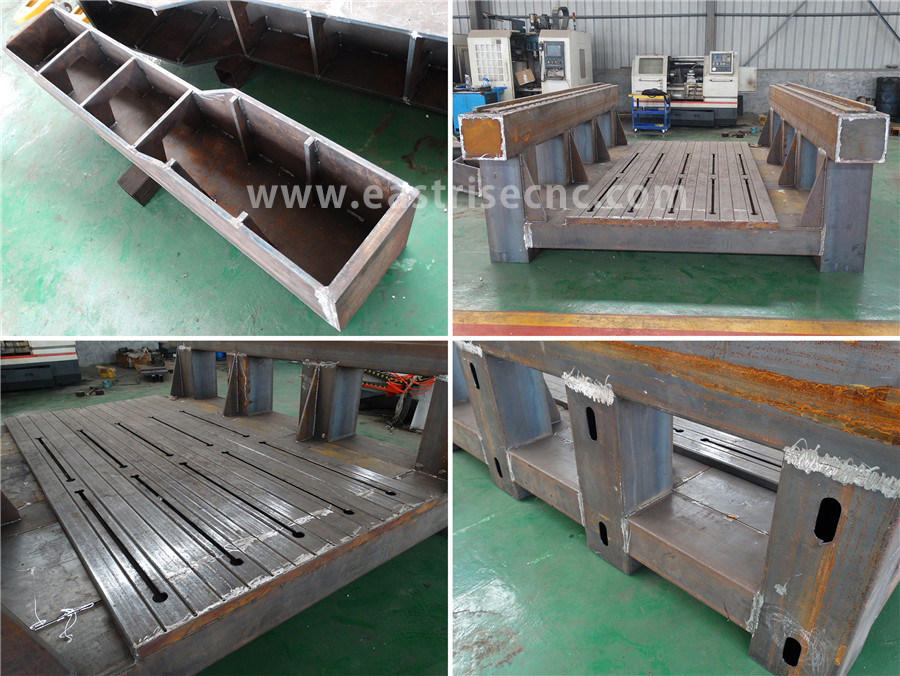

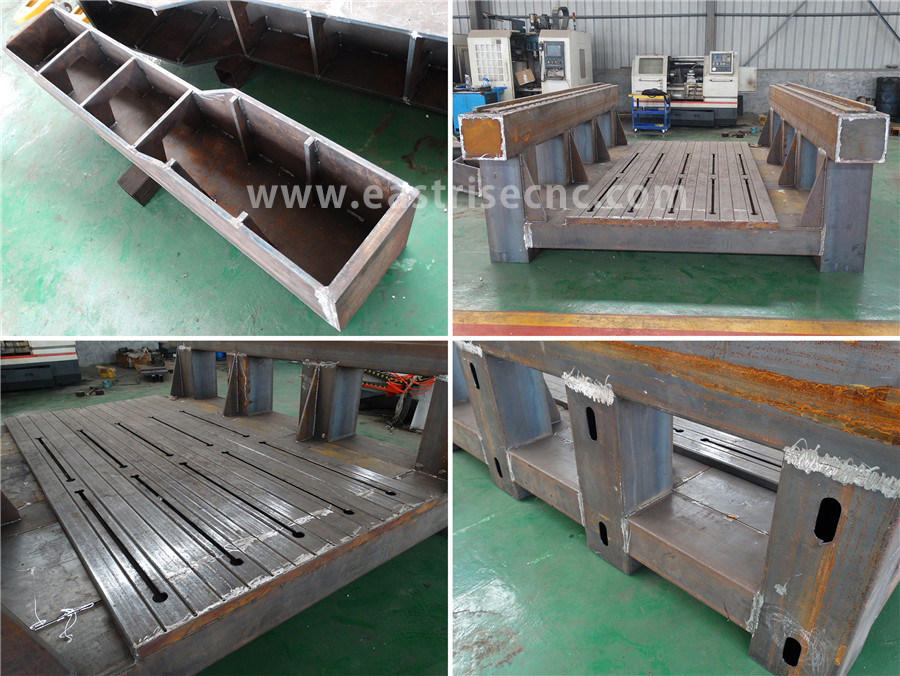

6. Whole cast steel structure thicken to 20mm.

7. Drive System: X, Y-Rack Z-Ball Screw, Z with high precision ball screw.

8. Automatic Tool Calibration: To guide rail and slide block , make it run better.

9. Schneider electrical components: original brand from France.

10. Japanese Omron Switch with long life.

11. APEX Reudcer from Taiwan: More powerful and higher precision.

Technical parameters

Description | ERB2040A 4AXIS |

X,Y,Z working area | 2000x4000x1200mm(optional) |

X,Y,Z Traveling Positioning accuracy | ±0.03/300mm |

Lathe-bed frame | Steel square tubes heavy duty body |

X,Y Structure | Rack and pinion |

Z Structure | Ball screw Taiwan linear rails |

Drive motors | Servo system |

Table surface | T-slot vacuum table |

Fixing method | 9.0KW air cooling pump |

Max rapid travel rate | 45000mm/min |

Max working speed | 20000mm/min |

Spindle | 9.0Kw Italian HSD |

Spindle speed | 0-24000RPM |

Working voltage | AC380V/50/60Hz |

Command language | G Code, *uoo,*mmg, *plt |

Flash memory | 512M |

Operating system | Taiwan Syntec controller |

Computer Interface | USB |

Collet | ER32 |

X,Y,Z working accuracy | <0.01mm |

Running environment temperature | 0~45 centigrade |

Relative humidity | 30%-75% |

Machining

Testing

Certificate

English

English