2026 CNC Glass Cutting Machine

Feature of glass cutting machine:

Cutting pressure automatic adjusted according to glass thickness.

- Cutter head 360 degree rotating.

- Climbing wheels on the cutter head for protecting the cutter assembly and the glass.

- Water proof surface panel, stainless steel side covered, water and deformation resisting

- High quality felt, perfect level, anti-static

- Self-lubricating guide rail

- Air filter for keeping the oil clean

- Air float and belt transmit

- Linear guide rail

- Automatic oiling for transmission system

Mechanical part of Glass Cutting Machine

1. Table: Imported waterproof/fireproof board is adopted. (Flatness≤±0.20mm/m).

2. Rack/Guide: Taiwan

3. Cutter wheel/wheel clamp: Germany.

4. Countertop: Korean imported industrial felt (black)

5. Tool holder: pneumatic and spring used together (to achieve the best cutting effect)

Electrical part of Glass Cutting Machine

1. Use PC computer for direct control, Microsoft Windows interface.

2. Voltage: 380V/50HZ. The equipment is equipped with a voltage regulator.

3. Motor: Yaskawa/Inovance servo motor. (It can also be equipped with domestic ordinary servo drive motor)

4. Professional supporting American Galil cutting software (used under WINDOWS operation interface).

5. Bring hundreds of cutting libraries. (It is convenient for drawing and operation)

6. The AUTO CAD drawing software is compatible with a complete set.

7. With automatic correction function. Ensure cutting accuracy.

8. Cutting path selection function. Ensure to achieve the best cutting speed.

9. Origin correction function. The origin of the secondary device can be used.

10. Operation input: keyboard and mouse. Chinese dialogue interface

11. Suitable for cutting straight, round and special-shaped glass of various thicknesses

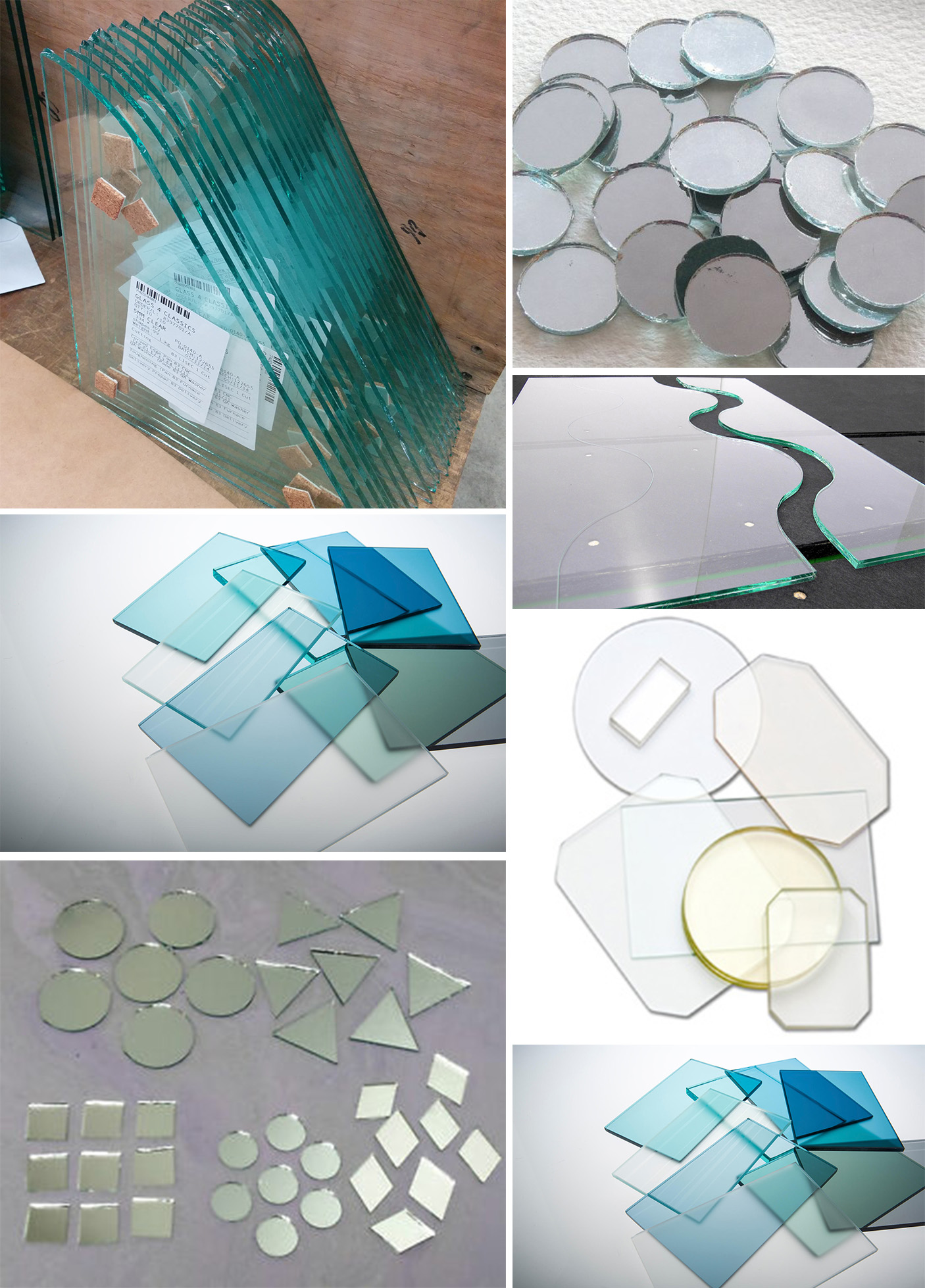

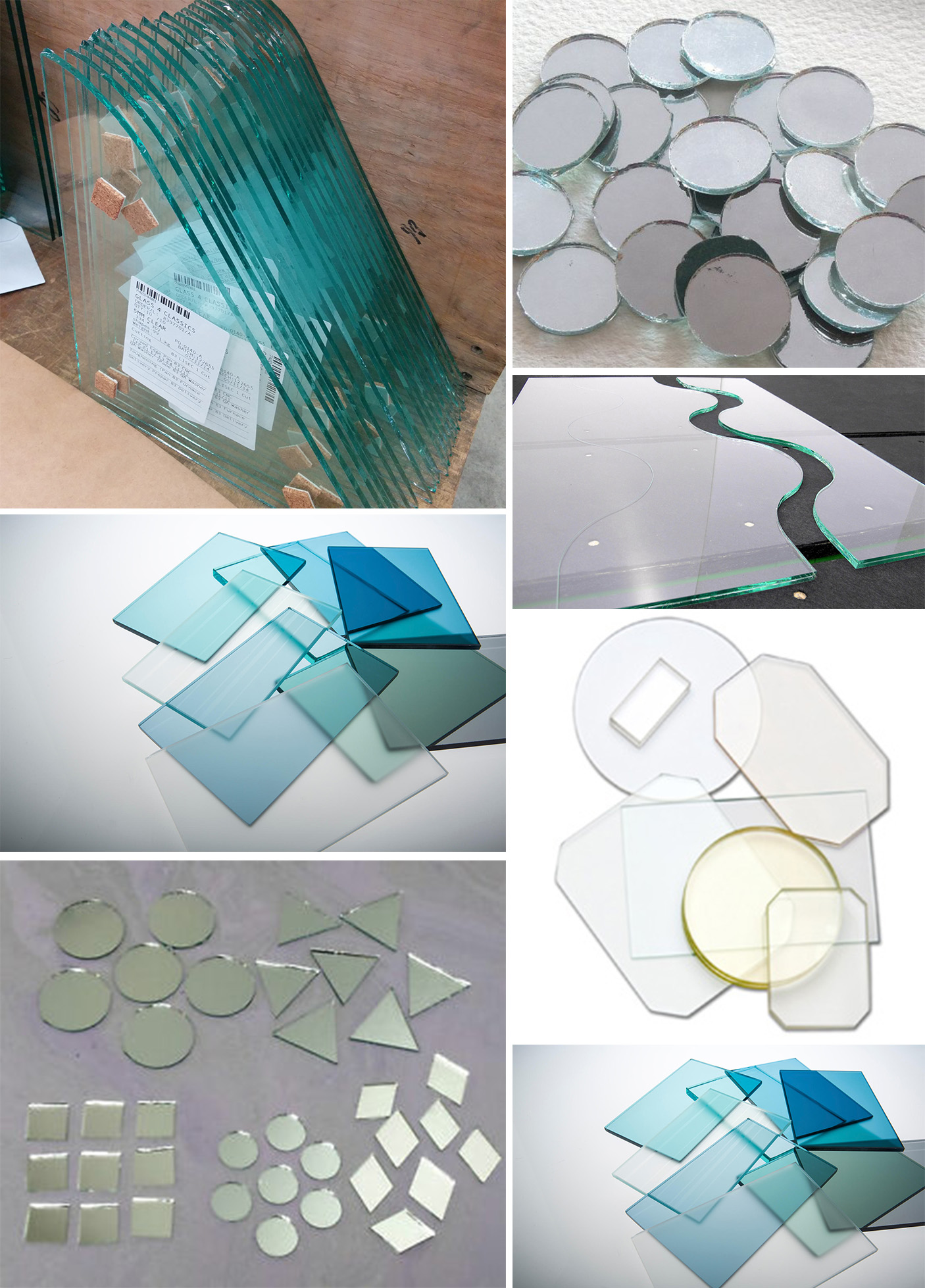

Samples of Glass Cutting Machine

Construction, hollow, furniture, home appliances, decoration, mirroring, auto glass, kitchen cabinets, bathroom and other glass cutting

Configurations

1. Transmission system: X, Y, Z axis adopt imported Yaskawa servo or domestic Inovance servo motor and imported precision gear unit.

2. Cutting knife holder: Air pressure and spring are used together, the knife head can rotate 360 degrees, and up and down cutting (can cut any shape of glass)

3. Oil supply mode: automatic oil filling.

4. Conveying device: air flotation device, convenient for glass movement.

5. Positioning: Pneumatic positioning system.

Machining

Testing

Exhibition

Certificate

English

English