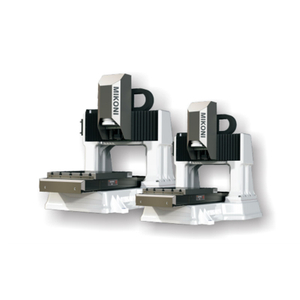

4040 400*400mm CNC Metal Molds Engraving And Milling Machine

Features of Mould Carving Router Machine

1.Whole machine structure is made of cast iron.Very heavy,net weight can be up to 1500kg.High strength and high stability mechanical structure design make sure the machine moves smoothly.

2.We use the milling machine technical, it is a top quality technical, it has a high precision and speed when it working, and it can keep the guide rails have a long service life.

3.About the paint of the machine, we adopt perfect processing technology.

4.Almost every assembly part will be measured by dial indicator, especially to measure both sides and guide rails,its distance is 0.01 mm,using dial to adjust the deviation is low Most,then keep accuracy and the machine can create more better products.

5.Our machines accept servo motors and drivers,one of the best brands in the world,with high speed, high power and torque.

Applications of Metal Milling Machine

1.It can process metal like bronze,aluminum,stainless steel,mold steel,to say nothing of nonmetal like MDF,PMMA,PVC,ABS board,KT board,wood,gemstone,marble,aluminum and plastic composite board,etc.

2.Suitable for engraving,carving,milling,drilling and cutting.

3.It is widely used in mould industry like injection molding,iron casting.

4.It can make mould like shoe mould,and it can also carve carfts like coin.

Advantage of Mould Making Machine

1. 3.5kw mould spindle is constant power spindle,specilized in processing metal with long life and high precision,stability.

2. Humanized controller: Simple and easy for freshman to learn and operate the machine. can support G codes

3. Gantry structure: Overall cast iron structure, stable structure, high rigidity and accuracy of 0.01mm.Double columns are an indispensable part that significantly increases the rigidity of the machine.

4.Delta inverter: On-board inverter is mainly used to control spindle start, stop and adjust spindle speed.

5. Servo motor and drives: from Japan with high precision and long life.

6. HIWIN linear guide rail:High positioning accuracy. It can realize zero clearancetransmission, strong rigidity, temperature rise is small.

9. Adopt table movement to keep stable and high precision.

10. Enclosed work space ensures safe and contamination-free work.

11.Oil lubrication system:The machine can be lubricate by user when the machine need to be lurbricated, so it is very easy and convenient to maintain the cnc router.

12. Stable and rigid structure: With the gantry type bed and table are one, it is not only good rigidity, but also no installation error for both. Processing precision will not be affected even if being used for long time.

Technical Parameters of Shoe Mold Making Machine

Model | ERJ4040F |

Working size | 400*400mm |

Max feeding height | 200mm(Customized) |

Max traveling speed | 6000-8000mm/min |

Tool diameter | ¢3.175、¢4 、¢6、¢8、¢12.7 |

Transmission | High precision Ball screw |

Software environment | WindowsXP/7/8/10 |

Spindle power | 3.5KW(Optional) |

Power without spindle | 1KW |

Voltage | 220v/380v |

Recognizing language | G code(nc)、mmg、plt、eng、dxf |

Spindle speed | 6000-24000rpm/min |

Control system | NC studio/DSP/Mach3/Syntec |

Machining

Testing

Certificate

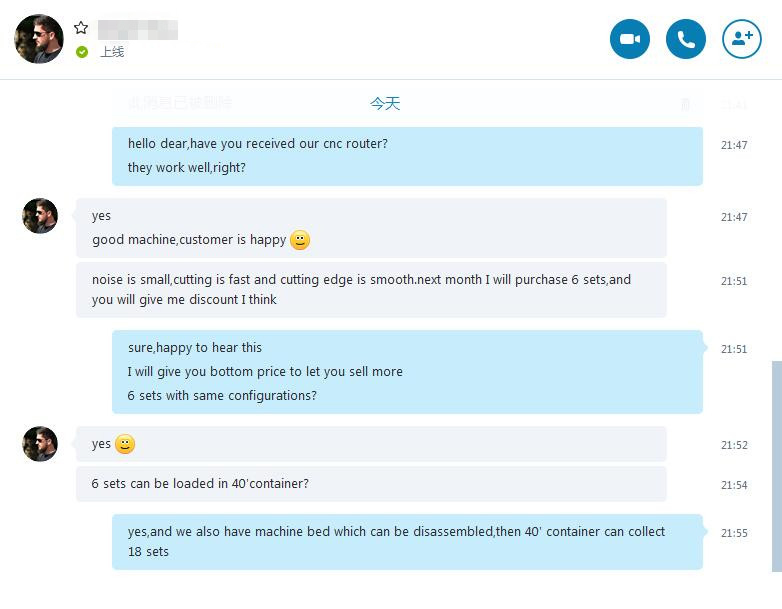

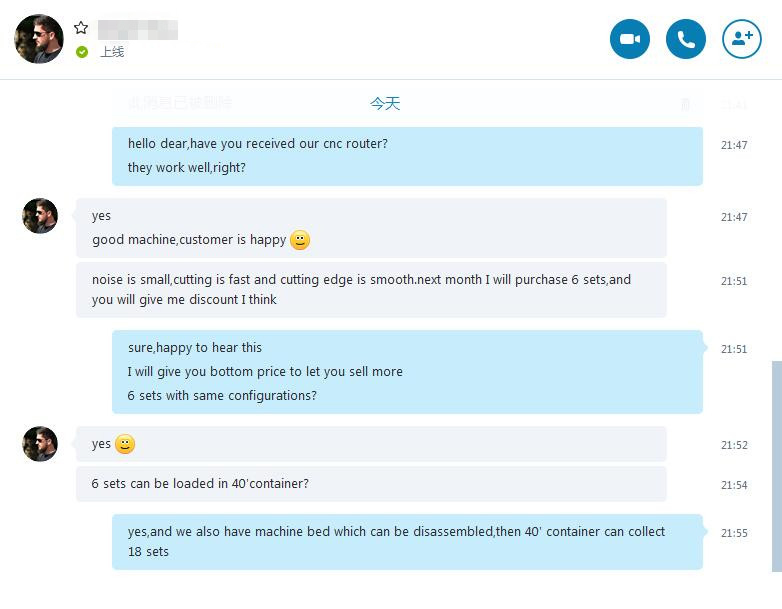

Feedback from customer

English

English