- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English- Home

- About Us

- Products

- CNC Router

- CNC Milling Machine

- CO2 Laser Machine

- Laser Marking Machine

- Fiber Laser Cutting Machine

- Plasma Cutting Machine

- Glass Cutting Machine

- Wood Lathe Machine

- Oscillating Knife Cutting Machine

- Water Jet Cutting Machine

- Woodworking Machine

- Letter Bending Machine

- Machine Parts

- CNC Milling Saw

- Wall Painting Machine

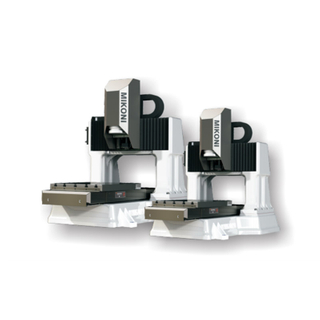

- CNC Machining Center

- Applications

- Service & Support

- Videos

- News

- Contact Us