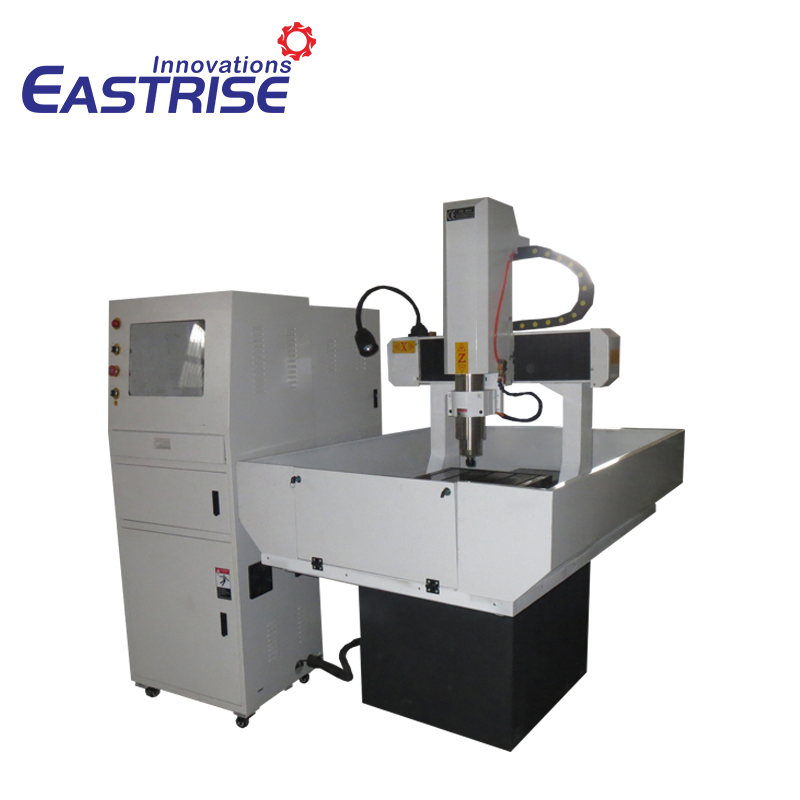

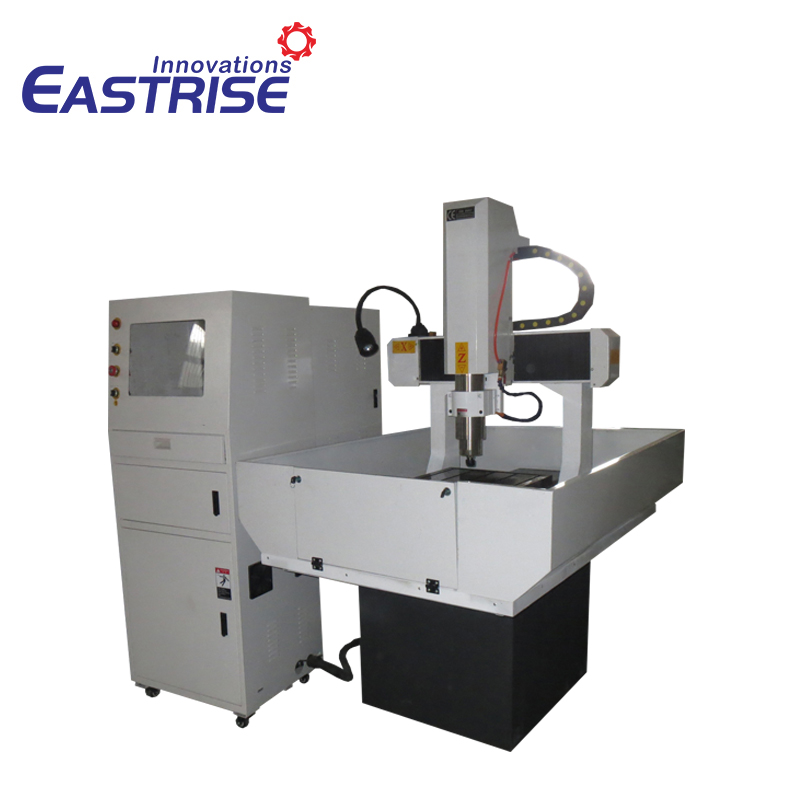

4040 400*400mm Semi-sealed Mould Making Machine,Metal Mould Cnc Router,CNC Metal Cutting Router

Applications of 400*400mm Metal Router

Small mold copper electrode processing

In terms of traditional mold processing, the PB/PQ series products of our company have been widely acknowledged by our customers due to their super machine tool rigidity compared with similar products, advanced CNC technology, impressive cost performance, high machine tool reliability, cutting efficiency and product finish. Our products will help customers substantially reduce expenses in mold-related machine tools.

Precision hardware and parts

The engraving and milling series machines manufactured by our company feature high rigidity, favorable stability, small processing vibration, and high accuracy of repetition, for which they are qualified for semi-finishing and surface finishing and have been widely applied to precision part machining and special aeronautical part machining. We have accumulated considerable experience in metal and non-metal part machining. The products our company provides are smaller in size and easy to build the automatic production line. With powerful after-sale services and excellent quality, they have been favored by an increasing number of customers.

Advantage of 4040 400*400mm Semi-sealed Mould Making Machine

1. Strive for excellence—reliable machine tool structure

Determined based on finite element analysis, the machine too structure is a box bed structure driven by center gravity (DCG). Larger ball screw and linear guide are used to ensure the ultrahigh requirement for machine tool rigidity.

2. Steady as a rock—Meehanite precision cast bed

Meehanite precision cast technology is applied, thereby ensuring zero defect and dimension precision of ever casting. Each batch of castings undergo 1-year natural aging treatment and manual aging treatment twice to ensure the stability and durability of bed precision to the hiit.

3.Every detail counts—imported processing detection devices to ensure processing precision

The only manufacturer that applies DMG machining equipment (DMG210P non-orthogonal five- :hogonal five- axis machining center) that is imported from Germany to make one-time machine shaping, thus ensuring a micron-scale bed precision. Every bed part undergoes RENISHAW online precision inspection* In addition, the Italian Hexagon three-coordinate inspection center is used, with a sampling rate of 20%. All these measures have made the bed precision of our products far ahead of other similar products.

4. Adopt high-speed water cooling variable frequency motor ,big torque,strong cutting ,high-frequency ,long-lifetime,can be a long time continuous working.

5. High cost-performance embedded hardware design, DELTA special servo series and spindles, and new-generation communication network DMCNET for high-speed data transmission and control to satisfy high-speed and high-precision mechanical cutting and machining.

6. Precision and smoothness control oJERK control, optimal corner decelerating control* o Processing speed will automatically decline at the bends along the processing path, thereby avoiding dramatic changes of acceleration, reducing mechanical vibration and maintaining long-term stability and precision of the machine tool.

Technical parameters

Model | ERJ4040S |

Working size | 400*400mm |

Max feeding height | 200mm(Customized) |

Max traveling speed | 6000-8000mm/min |

Tool diameter | ¢3.175、¢4 、¢6、¢8、¢12.7 |

Transmission | High precision Ball screw |

Software environment | WindowsXP/7/8/10 |

Spindle power | 2.2KW/3KW(Optional) |

Power without spindle | 1KW |

Voltage | 220v/380v |

Recognizing language | G code(nc)、mmg、plt、eng、dxf |

Spindle speed | 6000-24000rpm/min |

Control system | NC studio/DSP/Mach3/Syntec |

Machining

Testing

Certificate

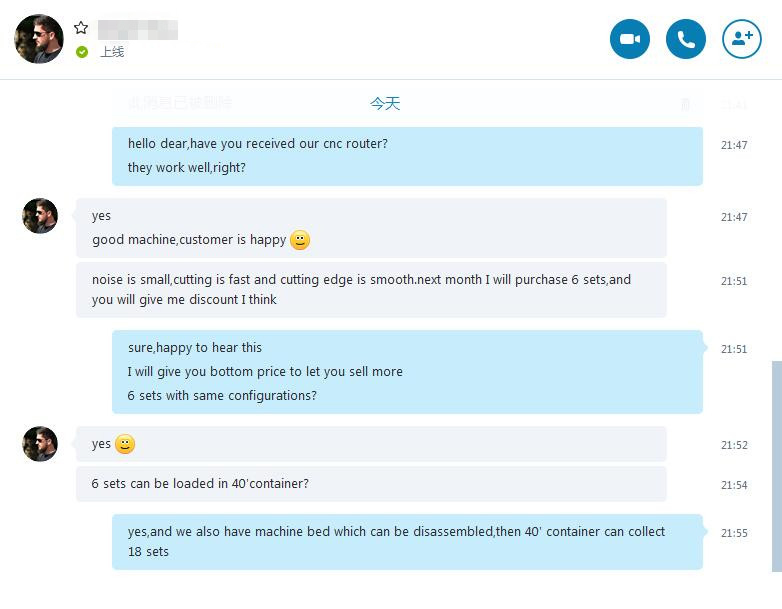

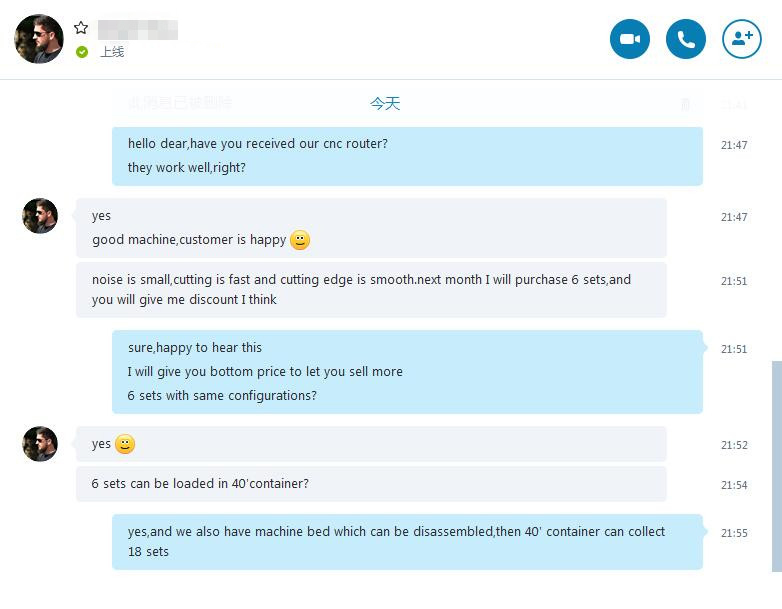

Feedback from customer

English

English