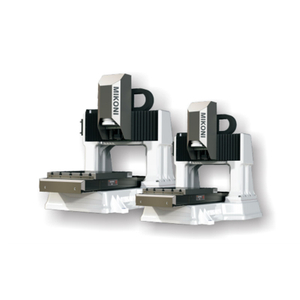

6060 600*600mm Semi-sealed Mould Carving Egraving Machine with Rotary Axis

Applications of Metal Carving Machine

This CNC mould making machine is suitable for making molds and other things,such as metal molds,drop molds,clock parts,red copper electrodes,shoe molds, handicrafts,jade products,crown milling and other forms.It is easy to create 2D or 3D solutions of different materials in this machine. It is ideal for batch processing of watches, glasses and small forms.

Mould Milling Machine Advantages

1.Cooling system: The spindle cooling system cools the workpiece and passes through oil or spray liquid through the nozzle or nozzle.

2.Quality assurance: Before each device leaves the factory, we will use a laser interferometer to test the hints.

3.The structure of the crane: the whole cast iron structure, the structure is stable, the stiffness is good, the precision is 0.01 mm. The double column is an integral part that significantly increases the stiffness of the machine.

4.A high-speed water cooled engine with high torque, high cutting force, high frequency and long life has been used, and can work continuously for a long time.

5.Servo motor and driver: from Japan, high precision and long life.

6.HIWIN Linear Guide: Made in Taiwan for linear piston stadiums.

7.Triaxial uses the German ball screw and Taiwan linear path to ensure the accuracy and accuracy of the reset.

8.Powerful and easy to use SYNTEC control system in Taiwan with excellent performance and competitive price.

9.Use table top movement to maintain stability and high precision.

10.A closed working space ensures safe and pollution free work.

11.CNC milling machine is a combination of CNC technology with engraving and milling. It is a multifunctional CNC machine tool. As with ordinary CNC machines, the price of our metal engraving machine is engraved on a CNC system, and the automation of milling automatically controls the motion of the engraving and milling machine in accordance with the part program code.

12.Sturdy rigid construction: the portal bed and the table are integrated, which is not only rigid, but also there is no installation error. Even if it will be used for a long time, the machining accuracy will not change.

13.CNC milling machine. CNC milling machine is a fully closed construction that uses oil treatment for external cutting. The whole body is cast, the structure is stable and the load capacity is high.

14.The CNC milling machine for making molds is equipped with the famous precision two-way ball screw, square rail made of Taiwan, precision bearings, high rigidity, high dynamic precision. It is also equipped with a YASKAWA AC Japanese servomotor, which has high precision and high power, which makes the amplitude lower and three axes more stable.

Technical parameters

Model | ERJ6060S |

Working size | 600*600mm |

Max feeding height | 300mm(Customized) |

Max traveling speed | 6000-8000mm/min |

Tool diameter | ¢3.175、¢4 、¢6、¢8、¢12.7 |

Transmission | High precision Ball screw |

Software environment | WindowsXP/7/8/10 |

Spindle power | 2.2KW/3KW(Optional) |

Power without spindle | 1KW |

Voltage | 220v/380v |

Recognizing language | G code(nc)、mmg、plt、eng、dxf |

Spindle speed | 6000-24000rpm/min |

Control system | NC studio/DSP/Mach3/Syntec |

Machining

Testing

Certificate

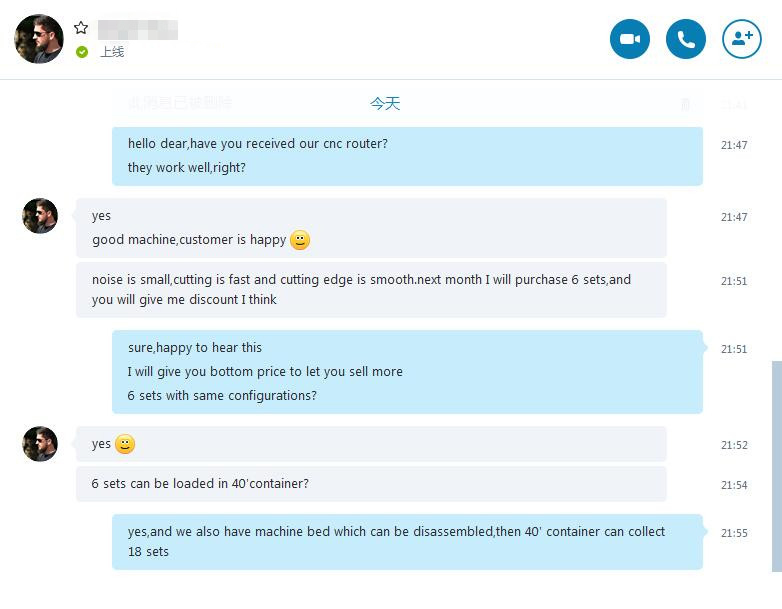

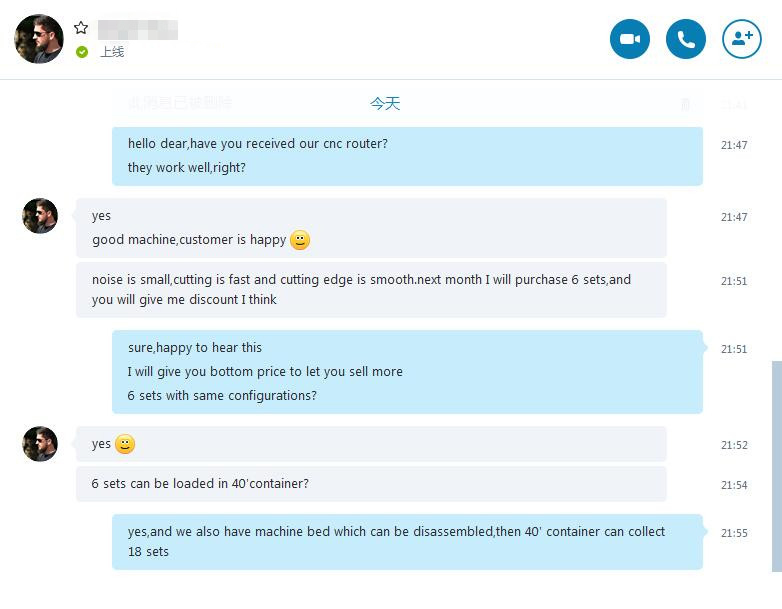

Feedback from customer

English

English