What Is Fabric Laser Cutting Machine?

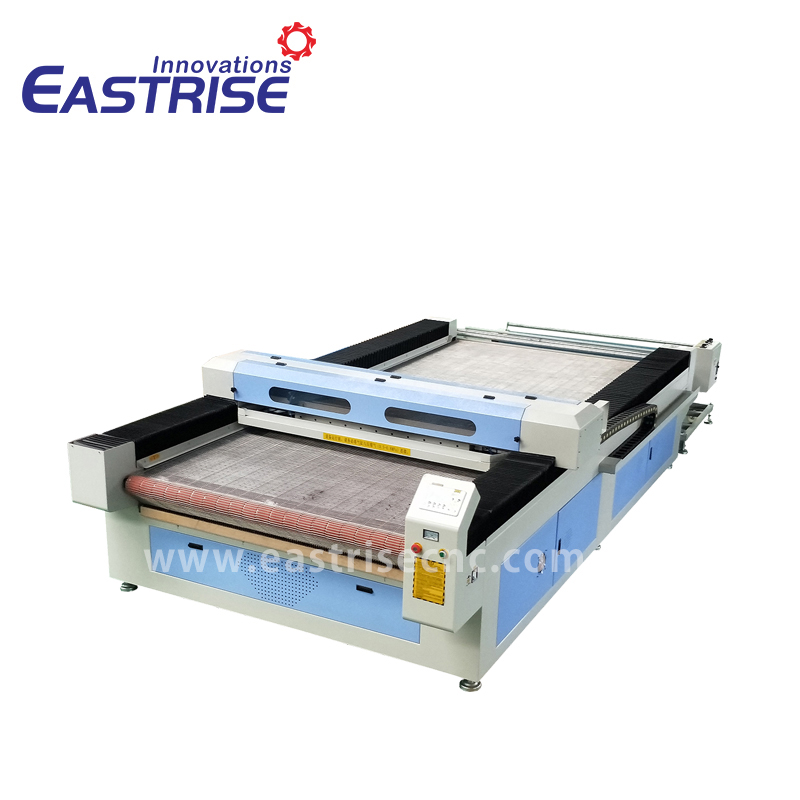

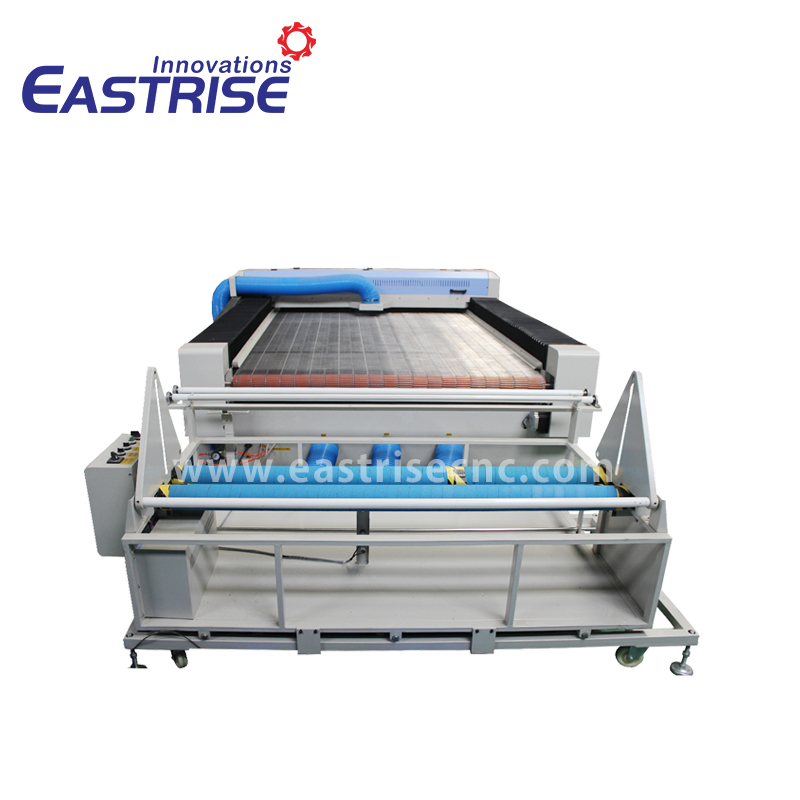

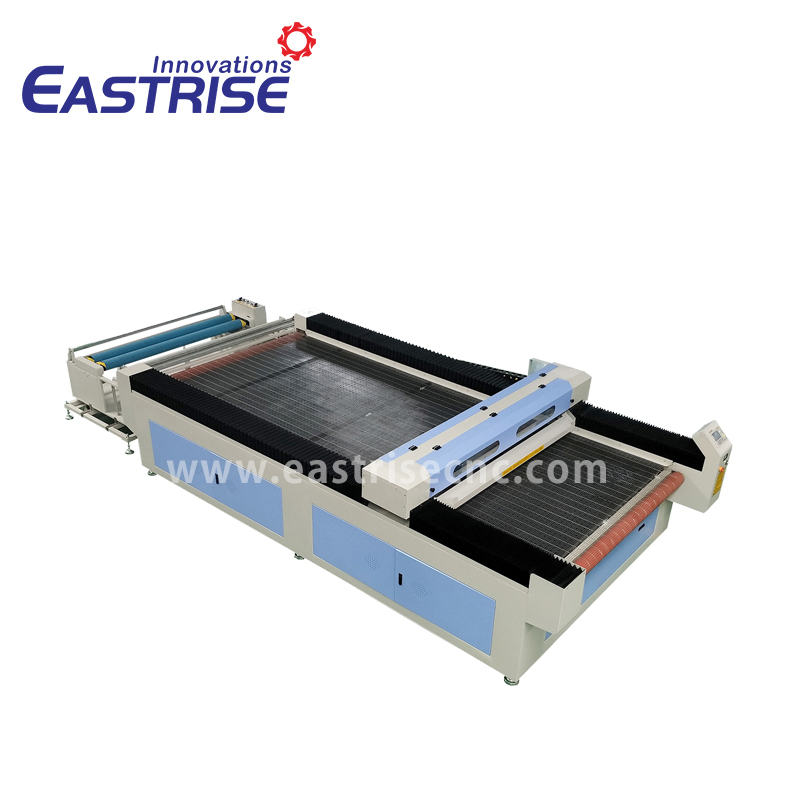

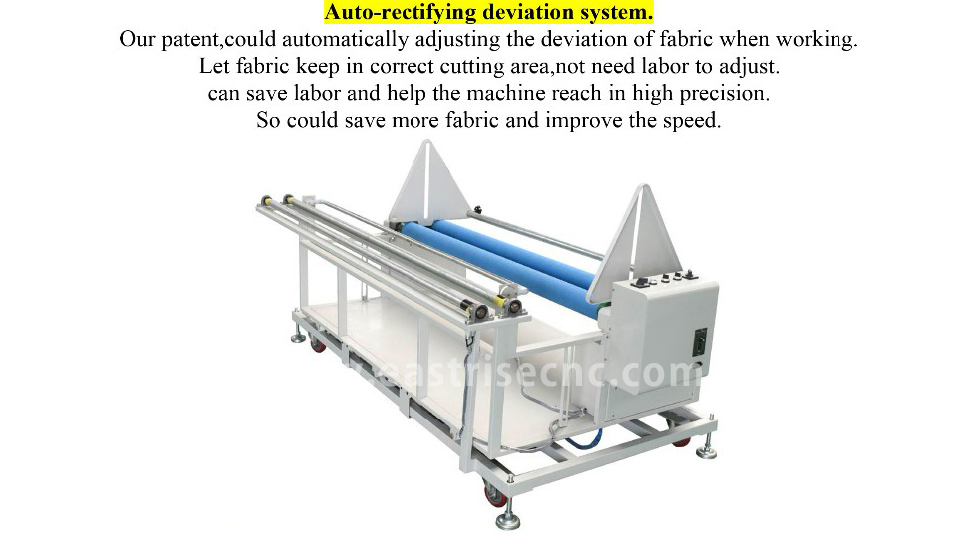

1, fabric laser cutting machine is a kind of industrial laser cutting machine, specially for the clothing industry, plush fabric cutting production, can be a variety of clothing fabrics for any graphic accurate cutting, can be equipped with feeding device, to achieve the continuous automation of the roll material cutting.

2, equipped with sealed on smoking, so that the marking and cutting process of the garment piece is completed at once, and the smoke produced during the cutting through negative pressure discharge, negative pressure adsorption and crawler transfer table, so that receiving and feeding materials is convenient and quick, processing out of the dust-free cloth non-woven fabric edges do not yellow, cutting fabrics including various colours of plush fabrics, non-woven fabrics, cotton and linen, synthetic fibres, and other materials, can be used with clothing photography copying machine, rapid production of sample clothes.

Advantage of Fabric Laser Cutting Machine

1.Fast cutting function: it can cut via any curve fast continuous cutting, the laser heads moving in beautiful arc just evoke your imagination of top grade racing car.

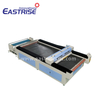

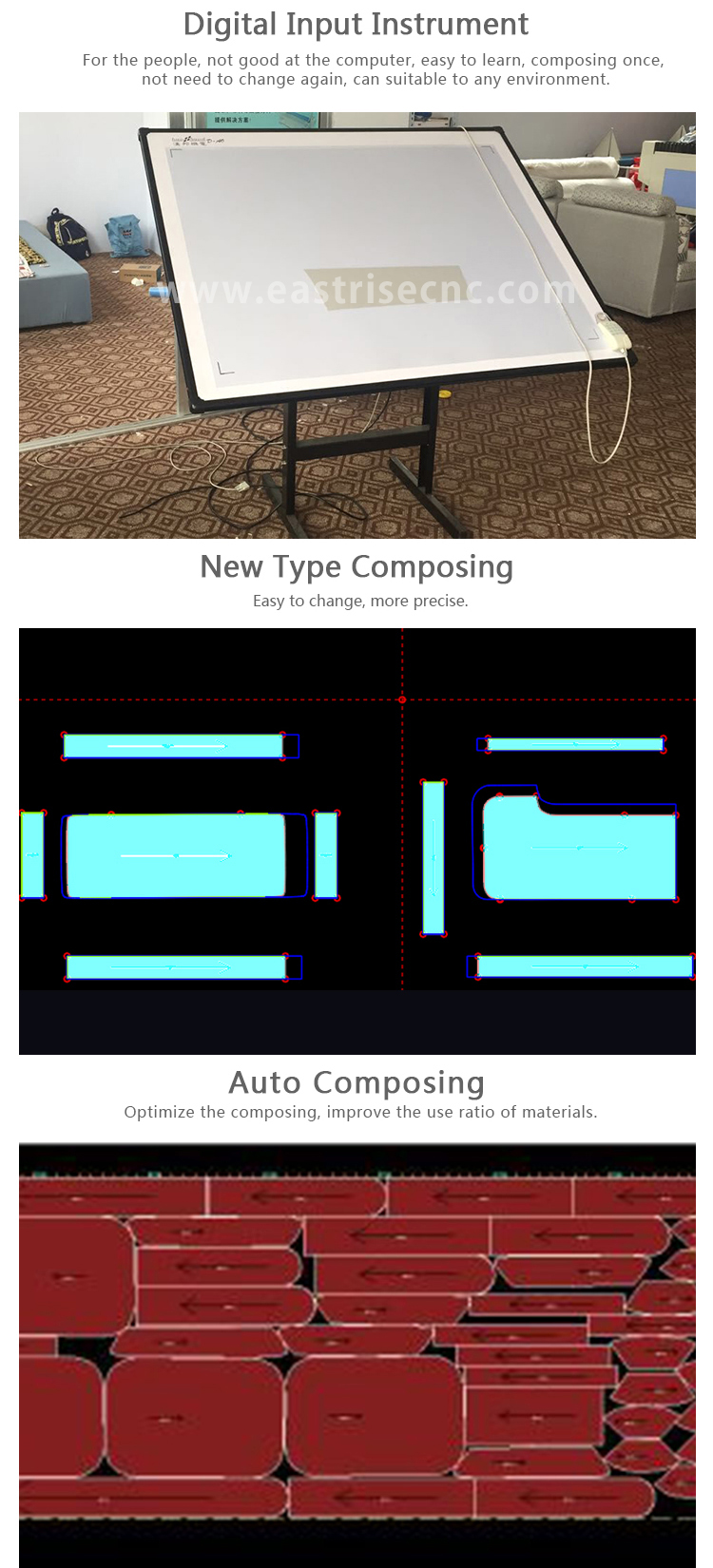

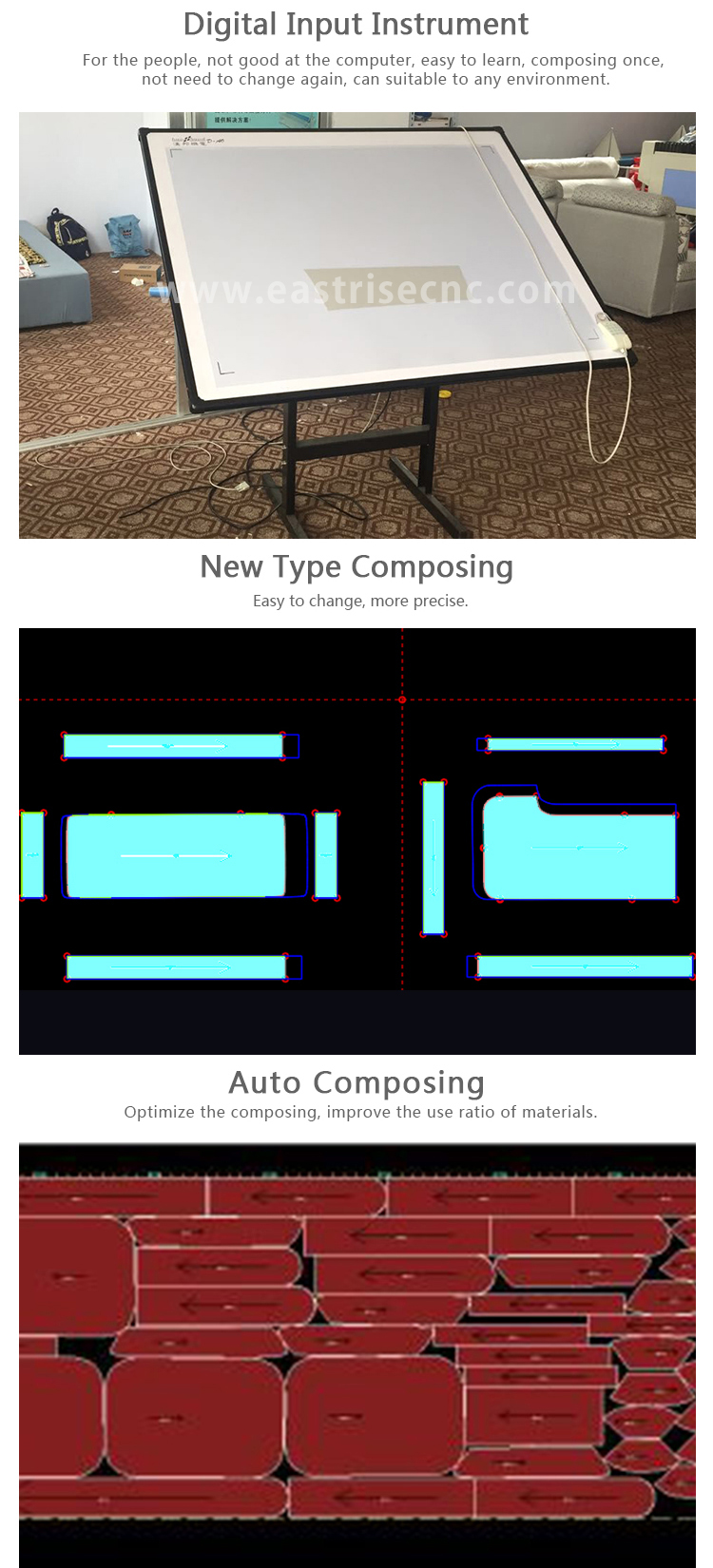

2 .To fully support design software, such as CAD, CORELDRAW, PHOTOSHOP, friendly man-machine interface, live close to the industry needs.

3 .Multi-document function: SC series equipment can store as many as 256 working documents, in the case of without the computer, the user can select files in the engraving machine, the mass production of 256 different products.

4. All-optical isolation system with high speed differential input and output circuit design, long distance transmission signal without distortion, strong anti-jamming capability, system has realized the no.12 working state output, state 16-way input, to dock with the user production site easily.

5.Large-format laser cutting incision smooth fine, meet the blanking, machining the whole piece of cloth.

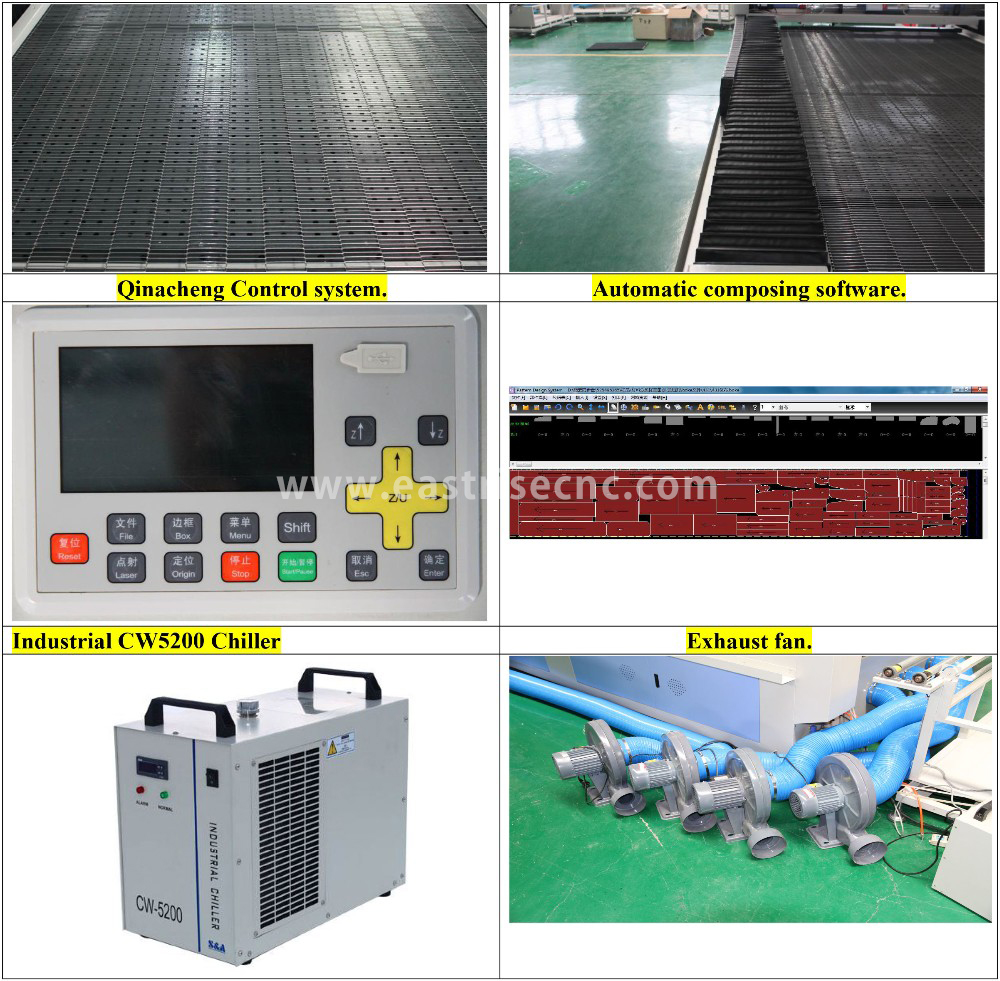

6 .Stable light path design, match industrial water-cooled machine, ensure the large-format, cutting the position work surface laser power output is consistent, fast and efficient, stable machining quality.

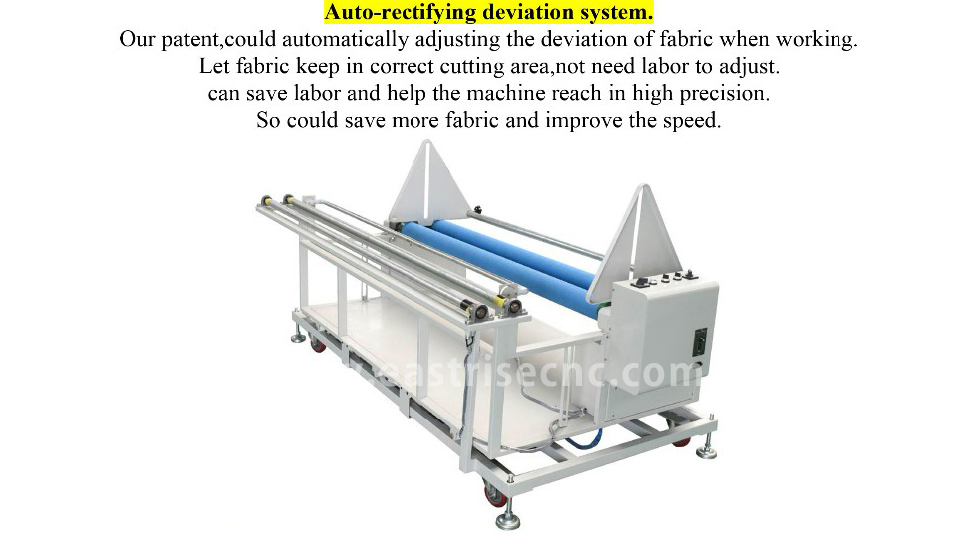

7. Automatic feeding and discharging, save time, improve work efficiency, it can customize according to customer's demand level.

8.Feeding system adopts special words with mesa, pedrail automatic feeding device, convenient processing objects move freely on the surface of the cutting machine.

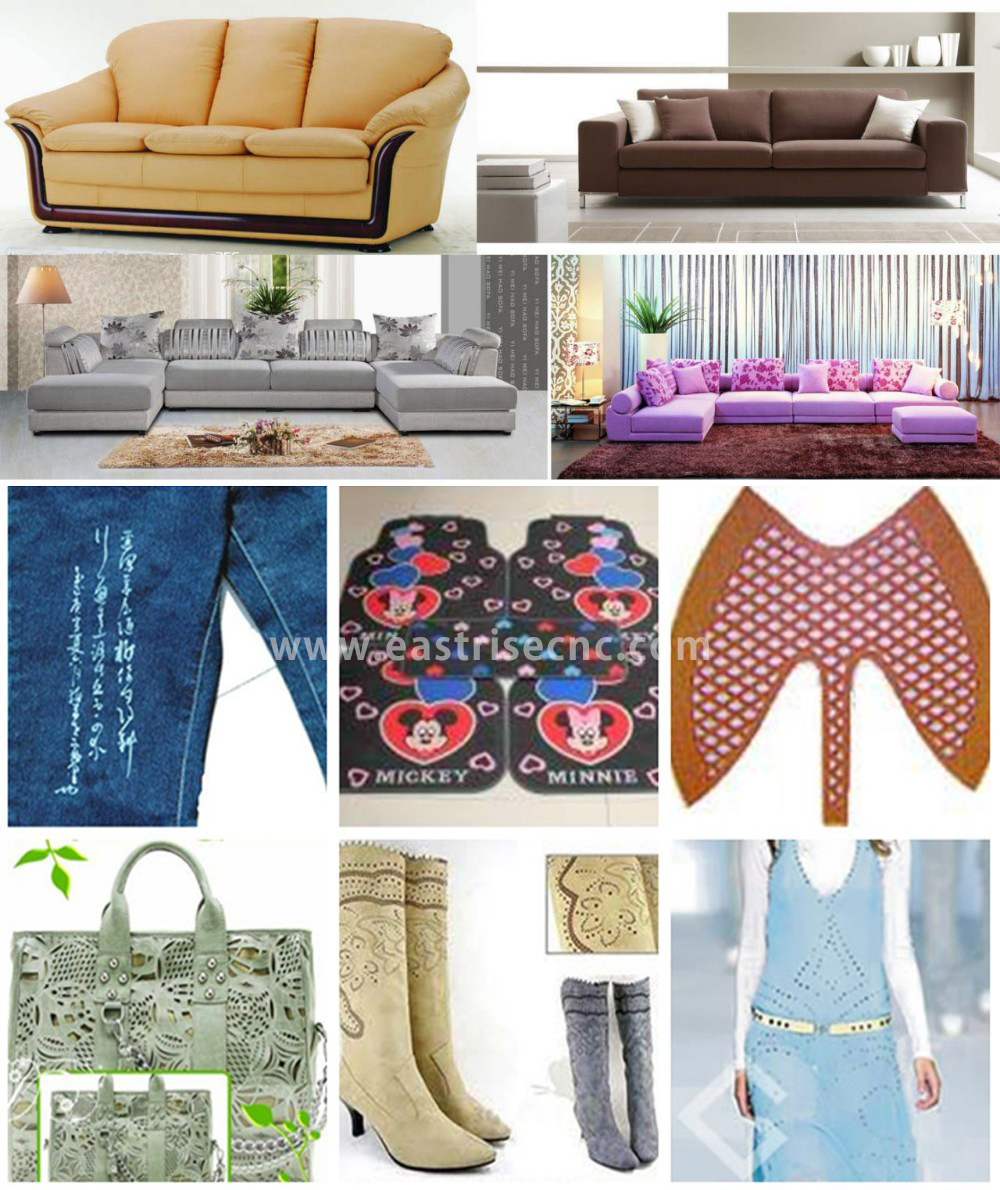

9.The machine used in clothing, textiles, leather and other industries.Mainly used for plate, cloth, leather and other non-metal cutting and carving.

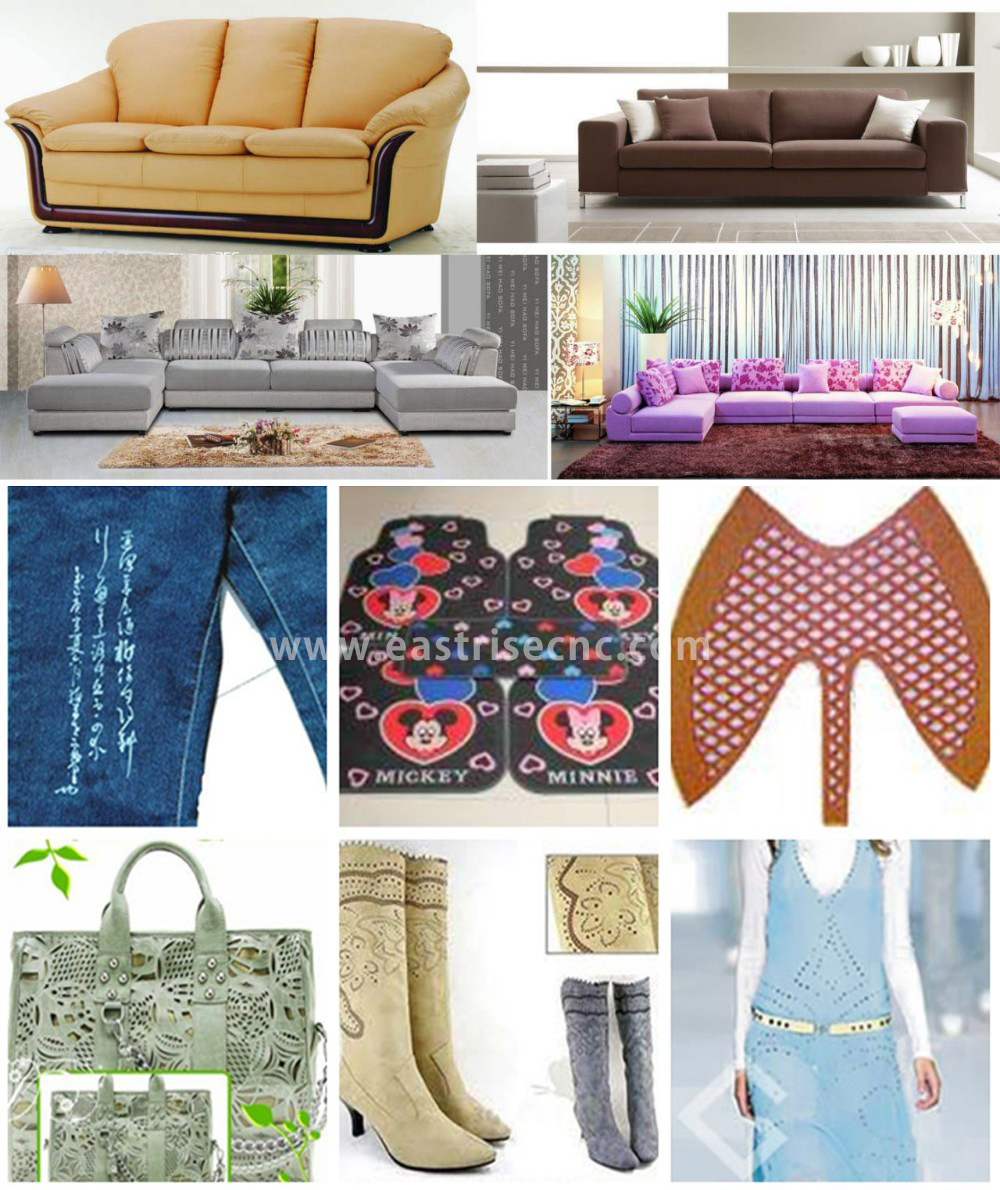

Application of Fabric Laser Cutting Machine

Genuine leather,artificial leather ,soft leather,decorative leather, packaging leather,etc. all kinds of leather,leather materials,pure cotton, real silk, all kinds of chemical fiber, jeans and so on .all kinds of textile materials, or non-woven material.

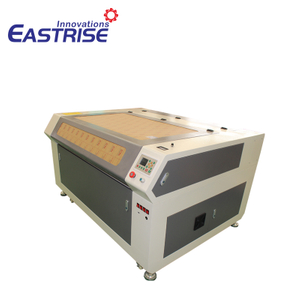

Technical parameters of Fabric Laser Cutting Machine

Working Area | 1600mm*3000mm |

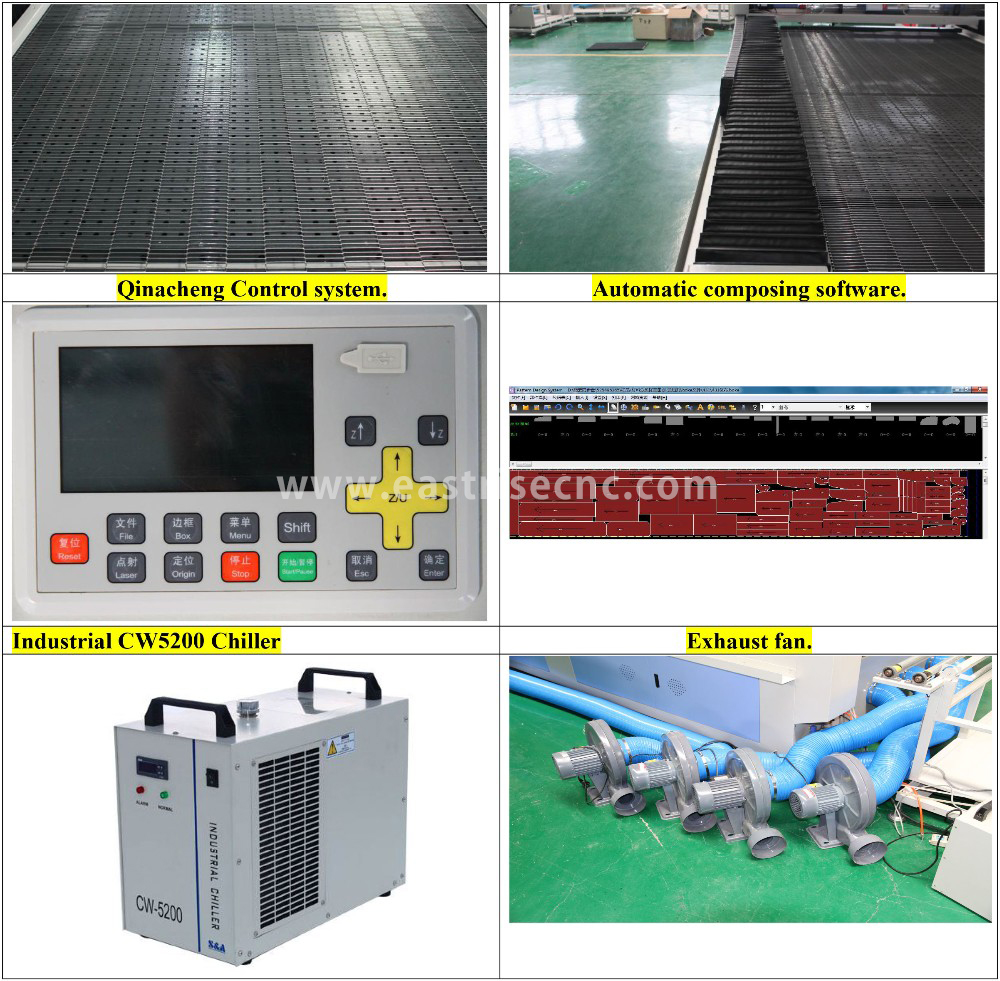

Software | RUIDA,QIANCHENG |

Controlling software | DSP control system |

Position System | Red dot |

Laser Power | 80W,100W,130W,150W |

Working table | Auto feeding conveyor |

Image Format Supported | BMP,PLT,DST,AI,DXF,etc |

Cooling System | Circulation water cooling |

Power Supply | AC220±10%,50-60Hz,30A max |

Driving Motor | stepper motor |

Working Temperature | 0-45℃ |

Working Humidity | 5%-95% |

Engraving speed | 0-800mm/s |

Cutting speed | 0-600mm/s |

Machining

Exhibition

Certificate

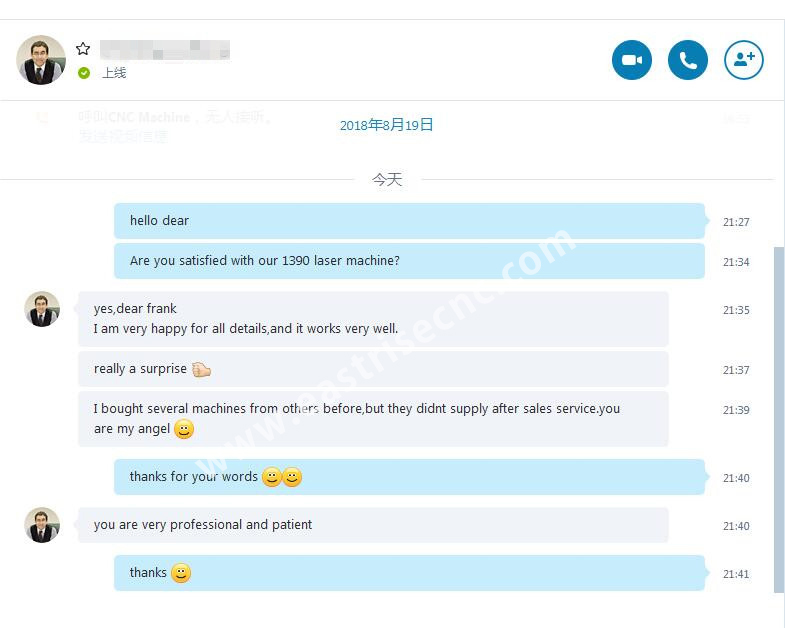

Feedback from customer

English

English