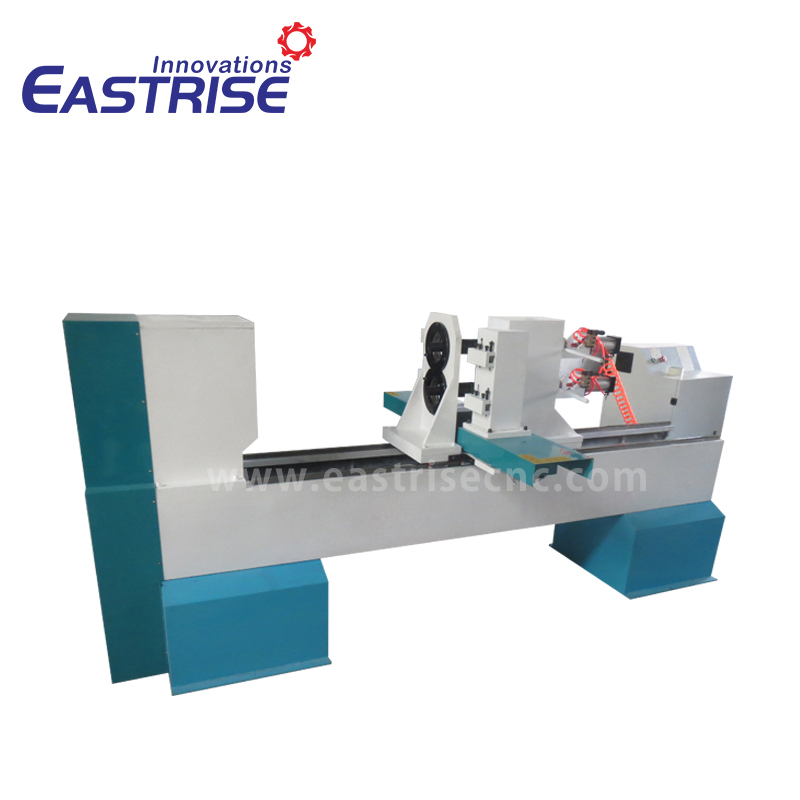

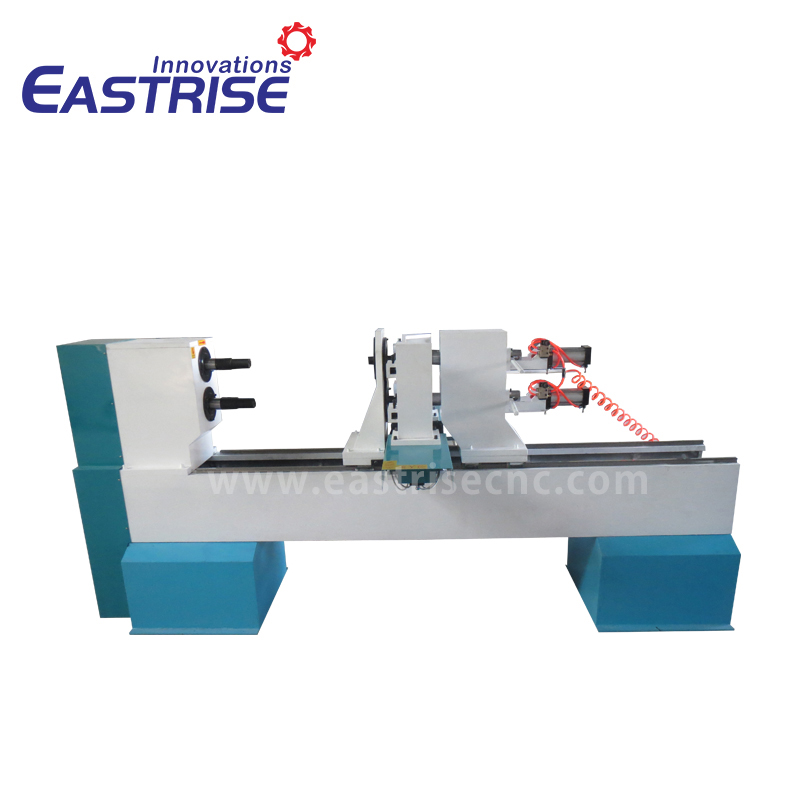

2-Axis Double Holders CNC Wood Turning Lathe

Advantage

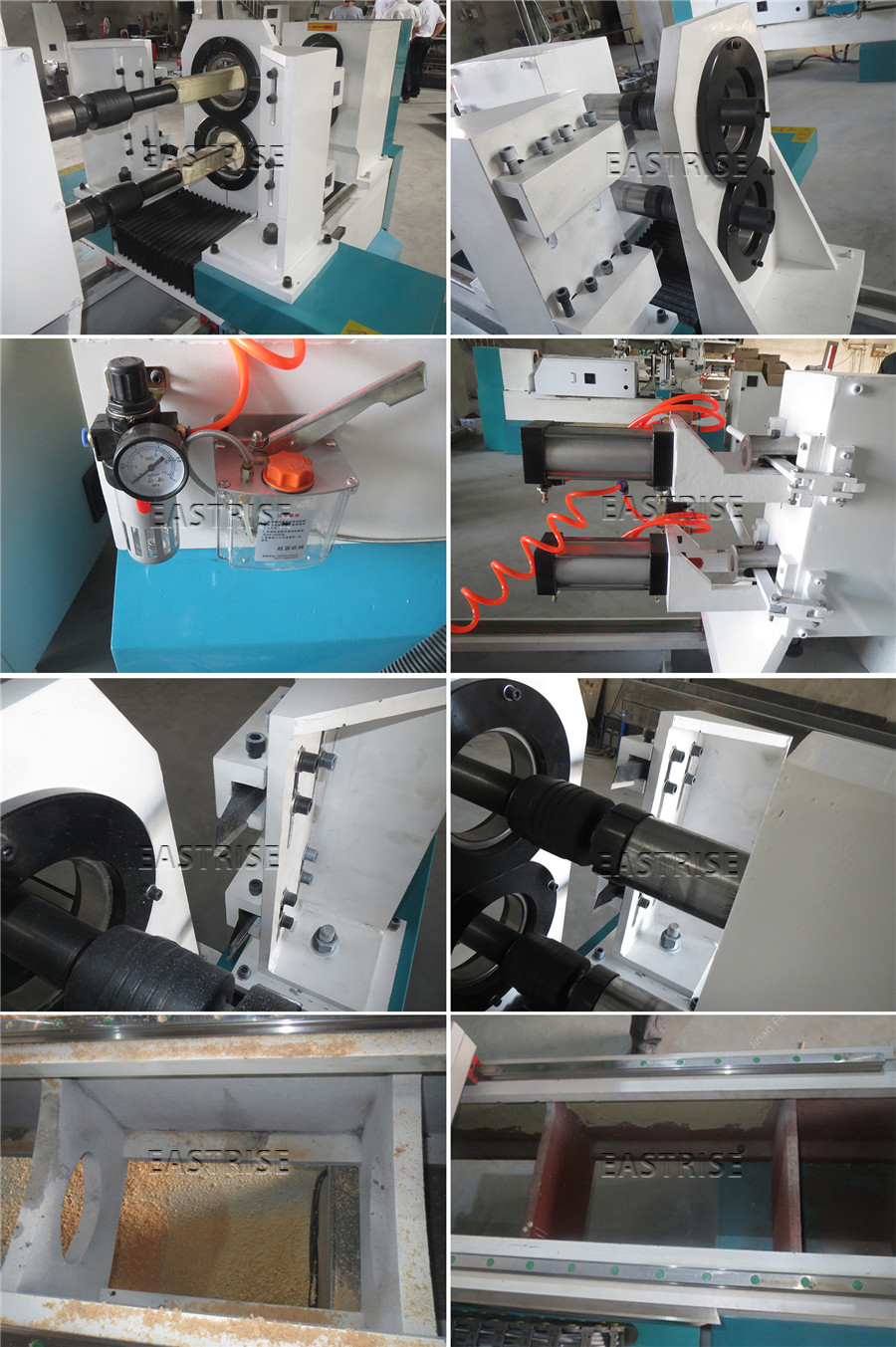

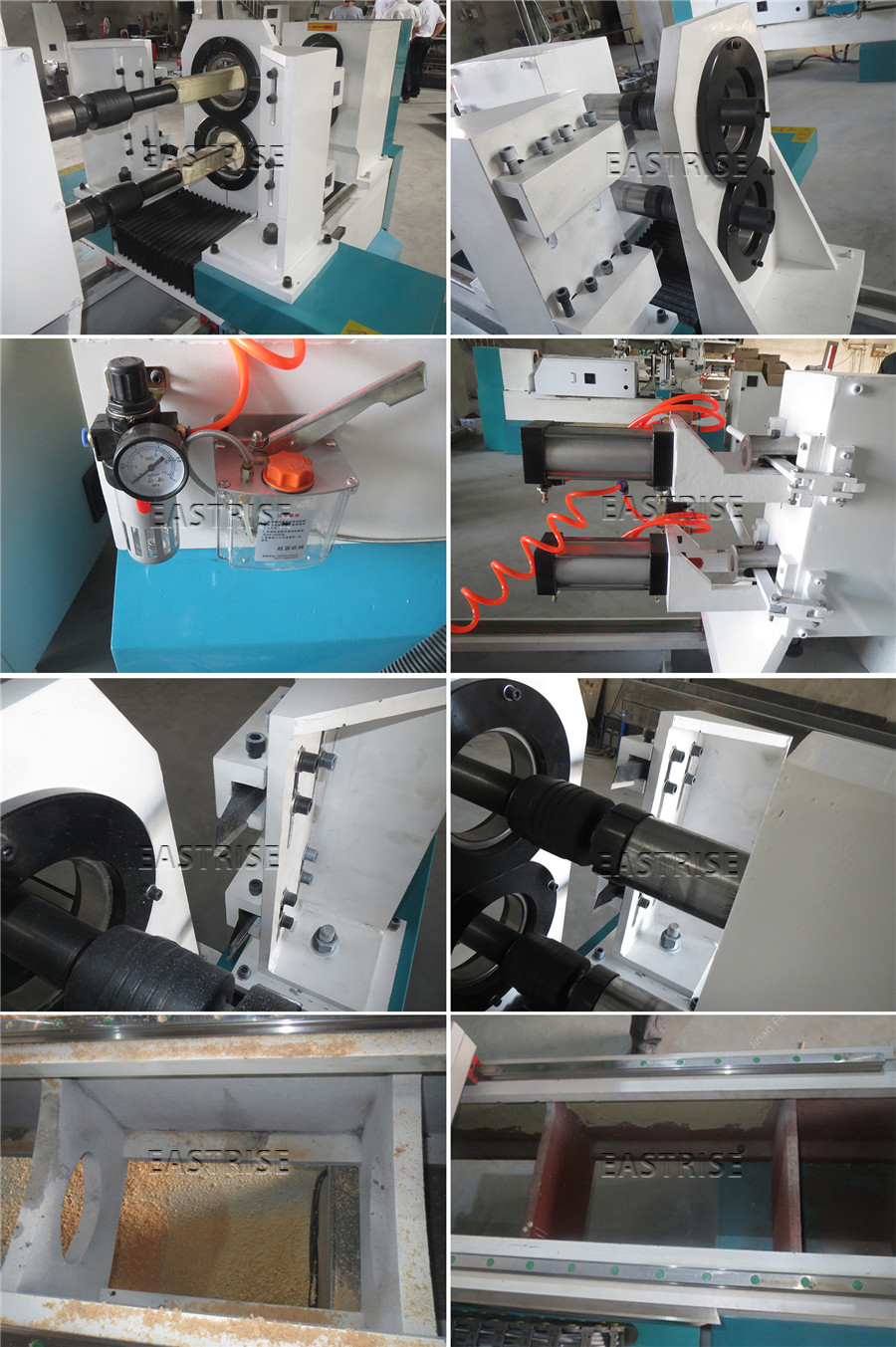

1. You can clamp the material on two clamps and machine the workpiece at the same time. One operator can run 2-3 parts of the CNC lathe at the same time to reduce labor costs.

2. The most advanced material loading skill: when you load the part on a CNC lathe, you don’t need to fix the part on the chuck, and then get the other edge of the part to find the center, and we load the workpiece, the 4-point lathe can help find the center ... And it only takes 3 seconds for all material loading material, with higher precision than automatic loading. For larger vases, you can use an automatic cutter and an adjustable air cylinder to improve surface finish and extend workpiece life. The center support fixes the center of the part in its own weight. It is a means of fixing the center of the part with greater precision.

3. Simple programming. Usually programming is an important step before getting started, as well as time consuming work. The CNC lathe program can help you shorten this time and improve your work efficiency for greater benefit. Programming can be handled with photography. When the photo is taken, scan and then can automatically enter the programming mode. And you can measure and resize directly on your PC.

Application

Various cylindrical parts, pointed bowl, pointed tubular wooden objects and vehicles, various treads for columns, balusters for stairs, new rucks for steps, legs for dining tables, legs for end tables, legs for sofa tables, bar stool legs, roman Column, Common Column, Sink, Wooden Vase, Wooden Table, Baseball Bat, Wooden Car Furniture, Crib Column, Chair Supports; chair stretcher; sofa and bun legs; bed rails; Street lights; baseball bats and so on.

Technical parameters

LATHE MODEL | ERL-1615-2 |

Max Processing Size | Length 1500,diameter 160mm |

Spindle Power | 5kw |

Quantity of Tools | 2 |

Max Feed Speed | 35mm/s |

Spindle Speed | 0-3500rpm |

Accuracy | 0.001mm |

Control System | DSP/GXK |

Support Command | International G Code |

Voltage | 380V/50HC |

Machine Dimension | 2750x1400x1500mm |

Weight | 1500kgs |

Machining

Testing

Exhibition

Certificate

English

English