Plasma cutting sample analysis

Views: 2 Author: Site Editor Publish Time: 2022-09-13 Origin: Site

Inquire

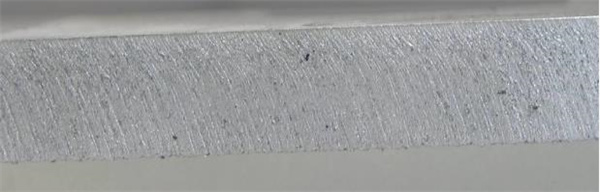

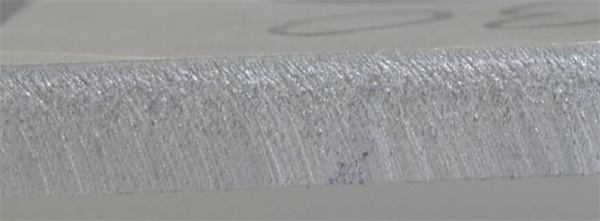

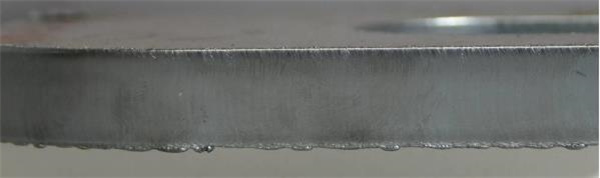

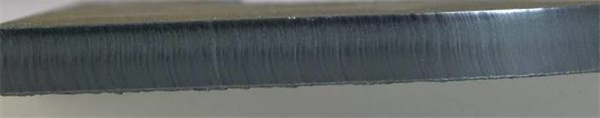

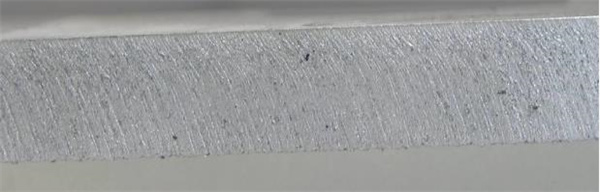

Aluminum

Cut speed too fast

Cut drag lines are more than 15 degrees trailing the torch (torch movement right to left) High speed bottom dross, easy to remove

Cut speed correct

Cut drag lines trail are visible, but cut surface is smooth. No dross

Cut speed too slow

Cut drag lines are more pronounced and cut surface is rougher

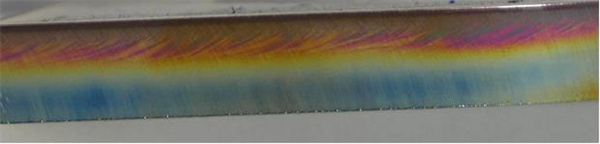

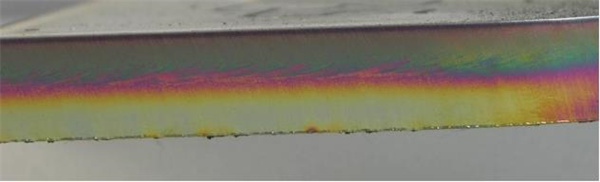

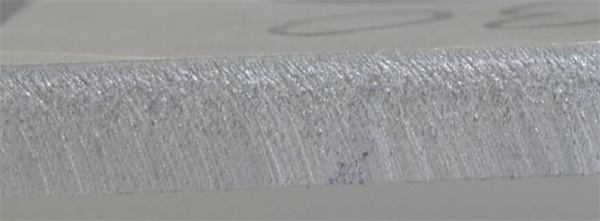

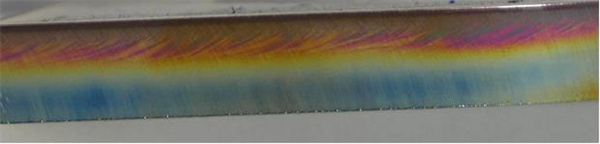

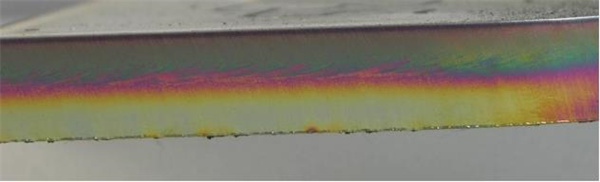

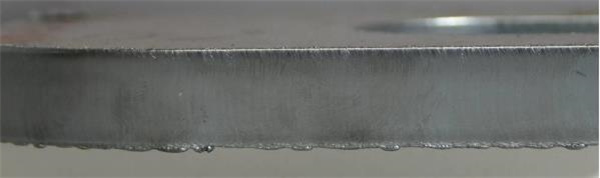

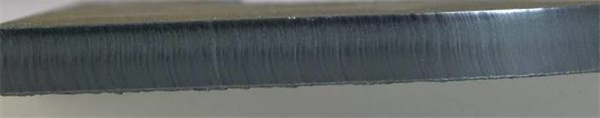

Stainless Steel (H35 plasma)

Cut speed too fast

· Gold heat discoloration swept in both directions

· Cut drag lines more than 15 degrees trailing

· High speed bottom dross, hard to remove

Cut Speed correct

Smooth cut surface . No dross

Cut Speed too slow

Heat discoloration is concentrated in the bottom half of the cut Hard bottom dross, hard to remove

Mild Steel (O2 plasma) Cut Speed Too Fast

Trailing cut drag lines

Light bottom dross, hard to remove, some top spatter

Cut Speed Correct

Cut drag lines near vertical. No dross

Cut Speed Too Slow

Cut drag lines lead the torch

Heavy bottom dross, easy to remove

Mild Steel (Air plasma) Cut Speed Too Fast

Cut drag lines curve and trail torch movement High speed bottom dross, hard to remove

Cut Speed Correct

Cut drag lines near vertical. Minimal dross

Cut Speed Too Slow

Cut drag lines vertical or leading the torch head Thicker bottom dross, easy to remove

English

English