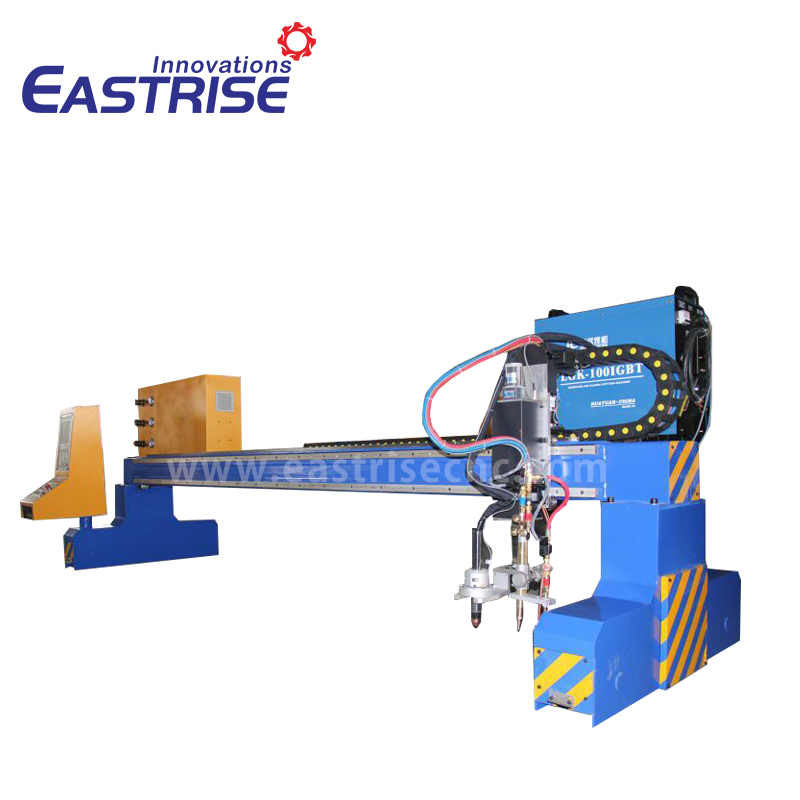

Big Size Gantry Metal Steel SS CS MS Plasma Cutting Machine

Features of Gantry Plasma Cutting Machine

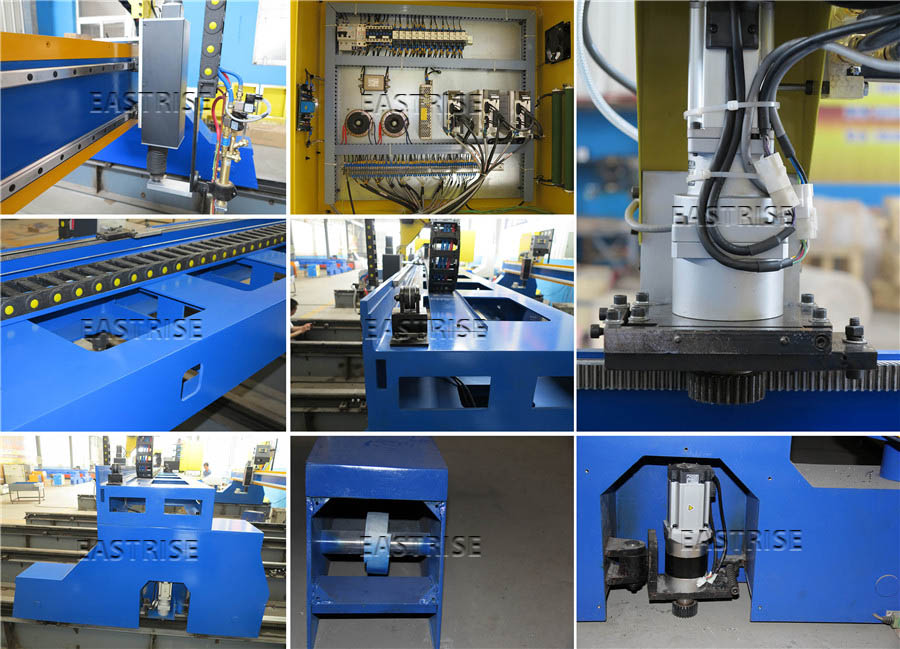

1. Thickened square tube welded structure with guide rail imported from Taiwan to ensure the speed and precision

2. Hypertherm power supply with high sensitivity arc pressure controller. The automatic adjustment can automatically select the best distance between the plasma gun and the workpiece to ensure high cutting precision.

3. CNC plasma cutting for aluminum, stainless steel using STARFIRE control system with FastCAM software for automatic material saving function, large capacity storage function, convenient reading and processing. .

4. The cutting head with cooling system can quickly cool the material surface to avoid burrs and residue.

5. General stepper motor with high precision rack and pinion to provide CNC plasma machine. The machine has low noise, smooth and precise coordinates for mobile performance.

6. Perfect compatibility of software such as Ucancam, Type 3, Artcum, etc.

Advantage of Gantry Plasma Cutting Machine

>cutting faster, more accurate control, the cutting surface is more smooth, no glitches, no black; cutting holes in high quality

>Stability and reliability for light path system and control system

>Humanizing design, convenient operation

>High performance price ratio, low operating cost

>High cutting efficiency and quality, no noisy. Small heat influence area, cutting seam smooth and no deformation, post treatment is not needed

>The machine adopt Beijing START plasma control system, standard high sensitivity arc voltage device

>High precision stepper motor and driver, ensure the efficiency and accuracy, increasing the stability and reliability greatly

Application of 1325 1530 Plasma And Flame Cutting Machine

Application Material: it is suitable for carbon steel, copper, iron, aluminum and galvanized sheet, titanium sheet,stainless steel and other metal sheet.

Application industry: it is widely used for processing shells of machinery and electronic products, advertising signs, crafts, iron garden, car manufacture, boat building, electrical accessories, board cutting.

Technical parameters

Specifications | Parameters |

Working Area(X Y) | 2000*6000mm 3000*8000mm |

Power source | Hypertherm/Huayuan plasma power supply |

Cutting Speed | 0-16000 mm/min |

Plasma Unit Max | 5.5KW |

Positioning accuracy | ±0.3mm |

Arc | Untouched arc striking |

Software support | FASTCAM plasma software |

Instruction format | G code |

Working table | Serrate working platform |

Working pressure | 0.3-0.7Mpa |

Working voltage | 3Phase 380V/60HZ |

Machine dimension(L*W*H) | 3000*2520*1540mm |

Weight | N./GW: 1500/1700KG |

Files transfer | USB interface |

Machining

Testing

Exhibition

Certificate

English

English