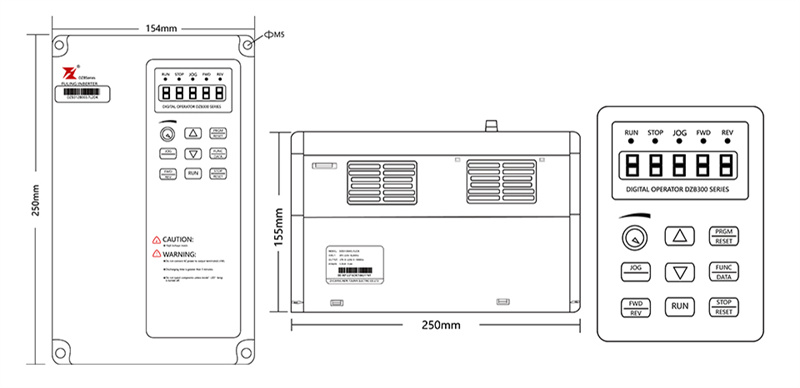

1 & 220V 380V 3.7 kw Variable Frequency Drive VFD/Inverter 0-1000H ausgang

Power: 3.7 kW

Input voltage: 220v (±20%)

Phase input: 1 or 3 phase

Input frequency: 50-60Hz (±5Hz)

Output voltage 220v

Output phase: 3 phase

Output current: 15A

Output frequency: 0-1000Hz

Control method: V/F control

◆Two speed control methods: V/F control

◆No PG vector control (SVC): starting torque 0.5Hz up to 150%

◆8-stage simple PLC function, multi-stage speed control and pid adjustment

◆Support multiple frequency settings: digital settings, analog settings, PID settings, RS485 communication settings

◆The I/O terminals can be freely programmed to combine multiple working modes according to user needs.

◆With frequency hopping control function, it can effectively suppress mechanical resonance and make the system more stable and reliable.

◆With instantaneous power failure retention function, it can avoid the impact on production caused by instantaneous power failure

◆With over torque and under torque detection

◆Automatic voltage regulation function, effectively solve the problem of low frequency vibration of high-power motor

◆Provide multiple fault protection functions: overcurrent, overvoltage, undervoltage, overheating, overload, lack of equal real-time monitoring and protection to ensure safe operation

◆Built-in reactor, the inverter power is greater than 37kW, which improves the power factor of the input side and improves the efficiency and stability of the whole machine.

◆ 0.75~15kW built-in brake unit.

Application

winding machine,mixer,extruder, slitter, winder, compressor, ventilator, pump, grinder, conveyor , elevator,centrifuger and other speed control machines.

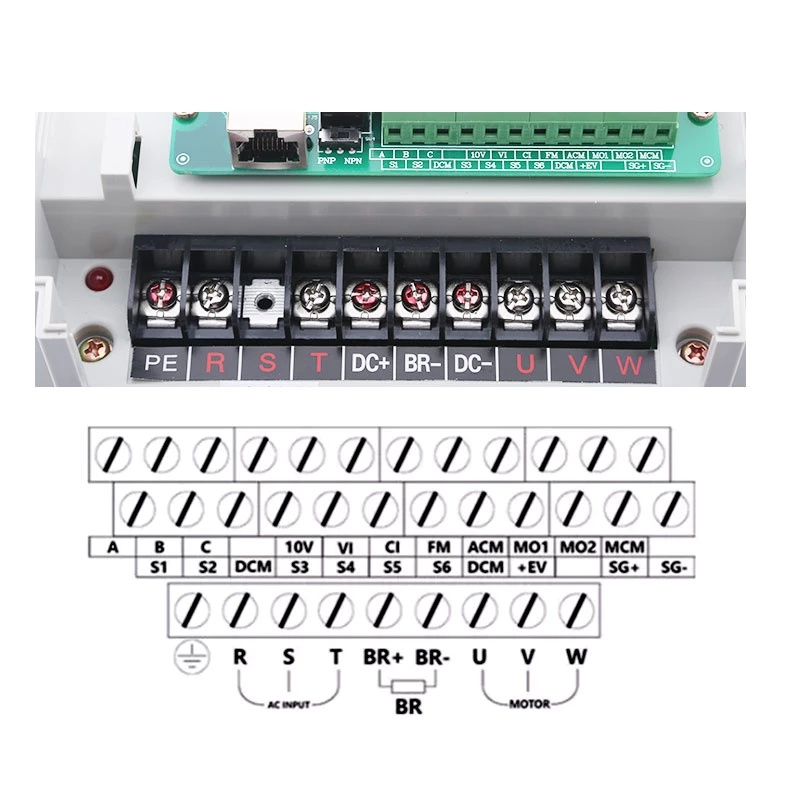

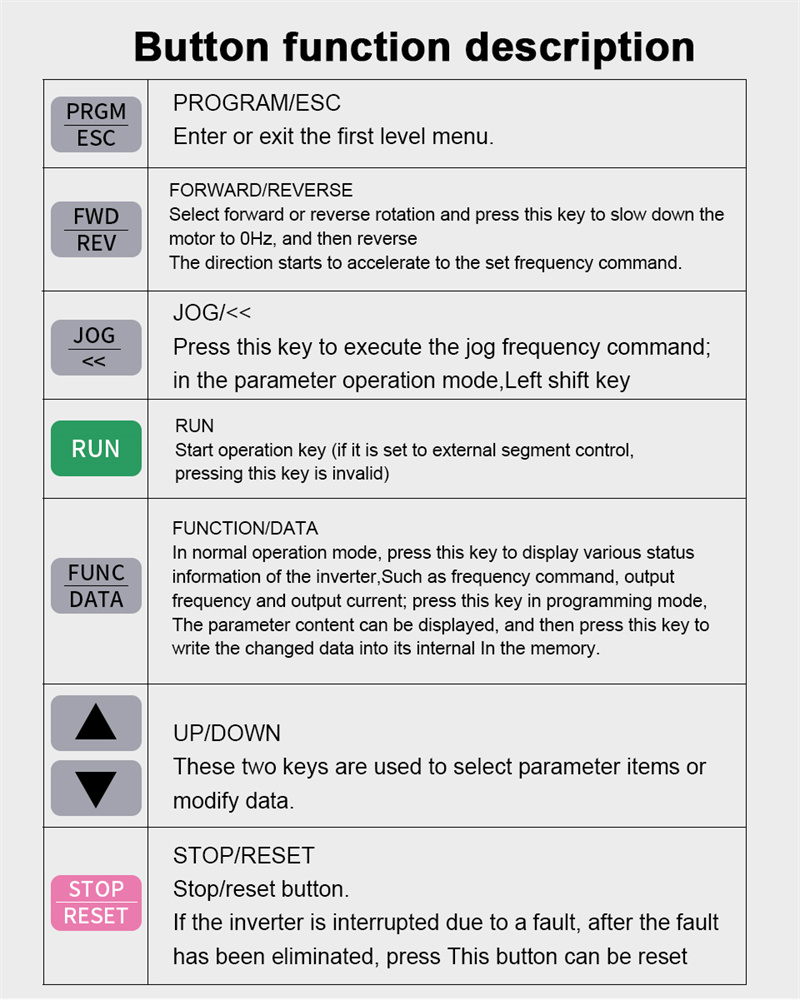

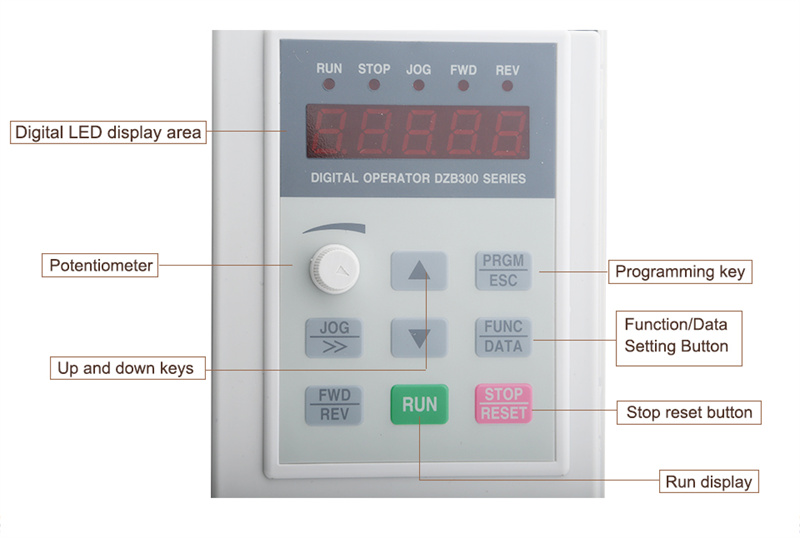

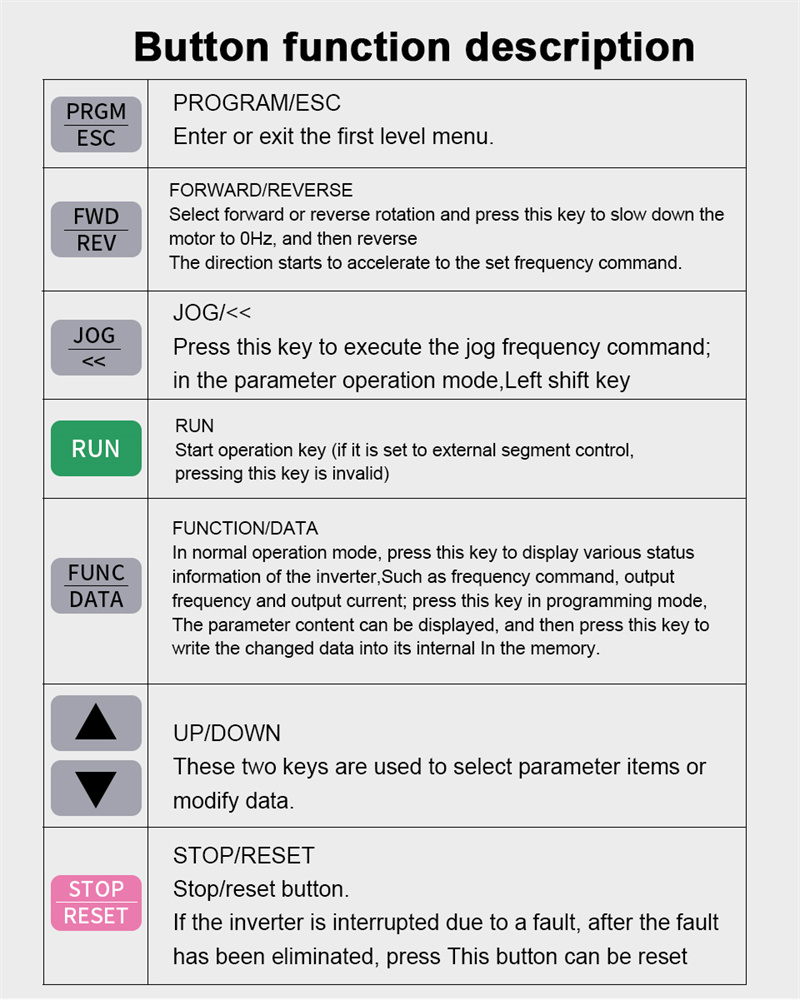

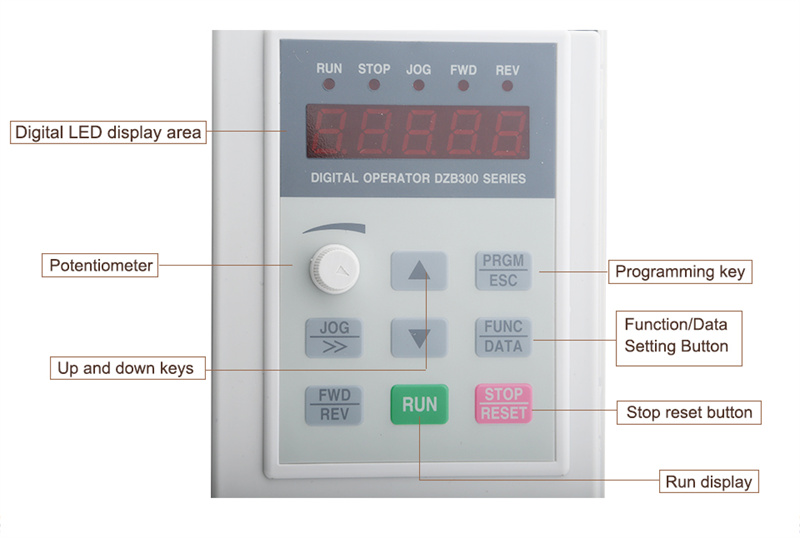

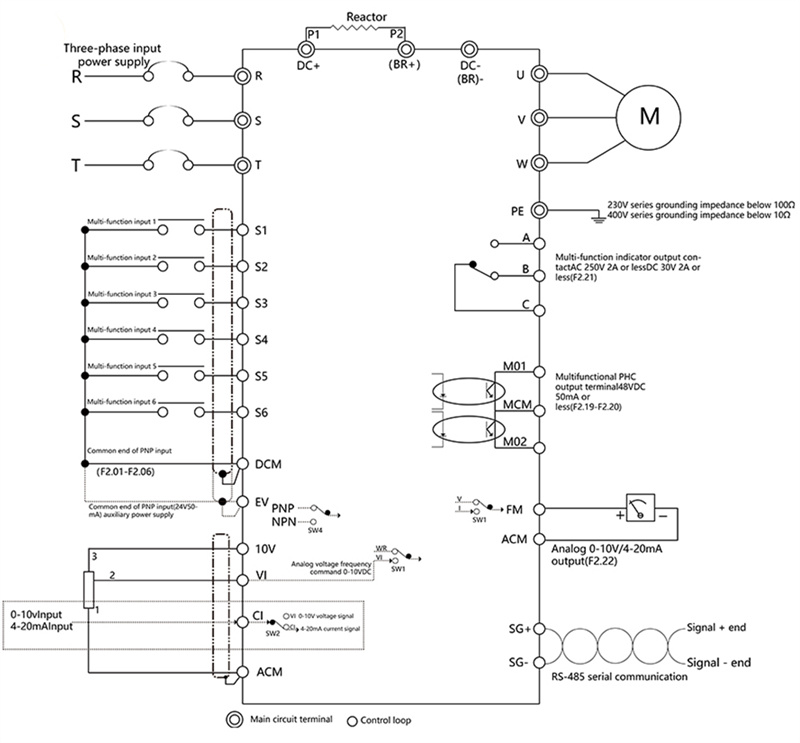

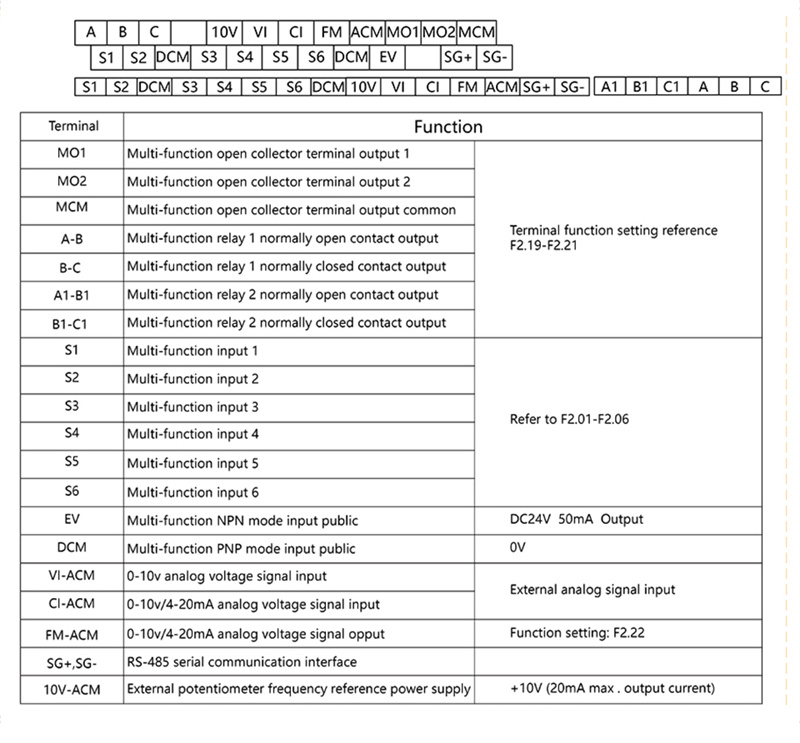

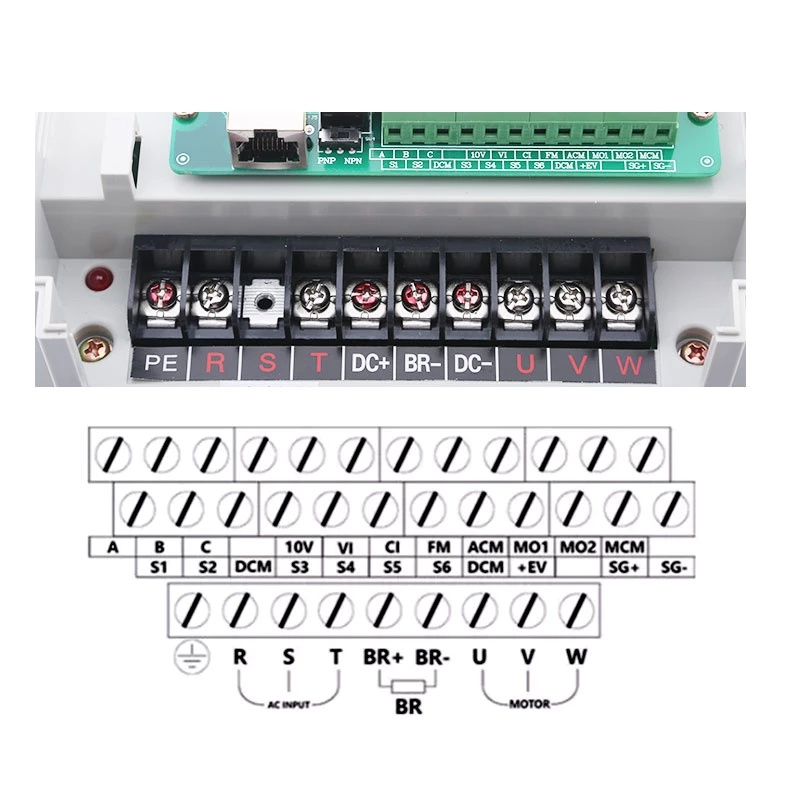

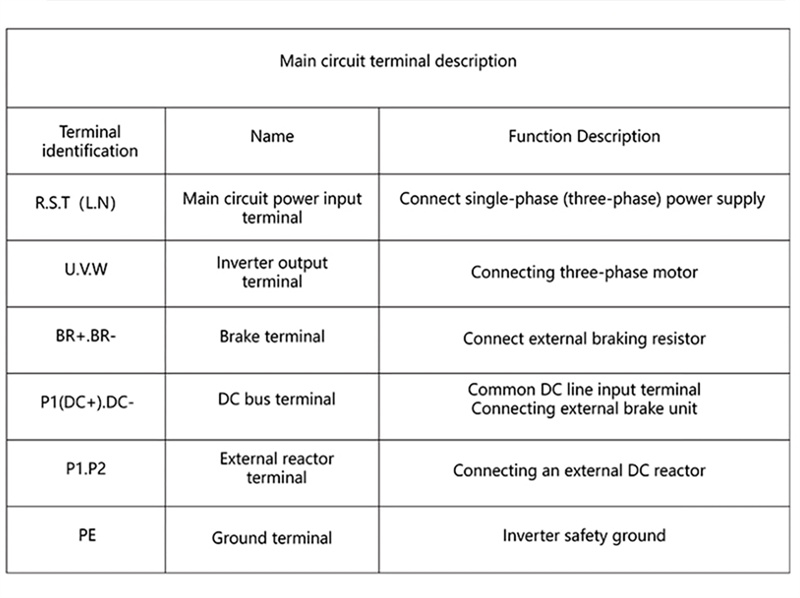

Panel operation instructions

NOTE:

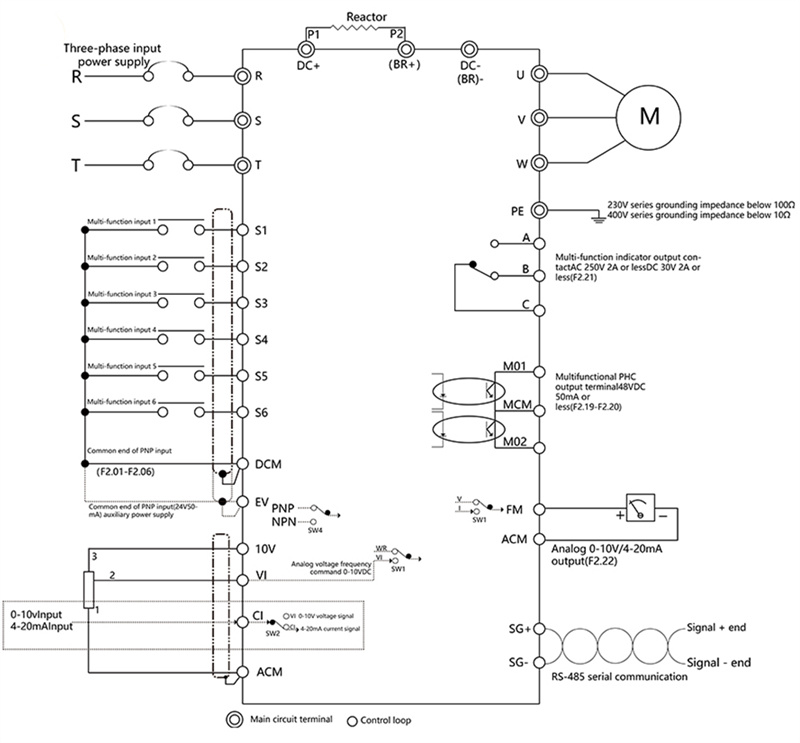

The above wiring diagram explained that only supplies the reference, take theactual product as the suandard, the diagram is subject to change without notice.

English

English