The choice of laser cutting nozzle

There are many types of fiber laser nozzles, which are used in different brands of machines. If you are not sure about the specifications, please consult customer service before placing an order to tell the nozzle height, outer diameter, single/double layer, and what kind of plate to cut.

T2 copper production

Excellent conductive heat, high hardness, corrosion resistance

Cutting thick plates without pressure

Single layer:

The single-layer nozzle uses nitrogen and air as auxiliary gas to cut stainless steel, aluminum, copper, etc.

Double layer:

The double-layer nozzle uses oxygen as an auxiliary gas to cut iron plates, etc.

Operation tips

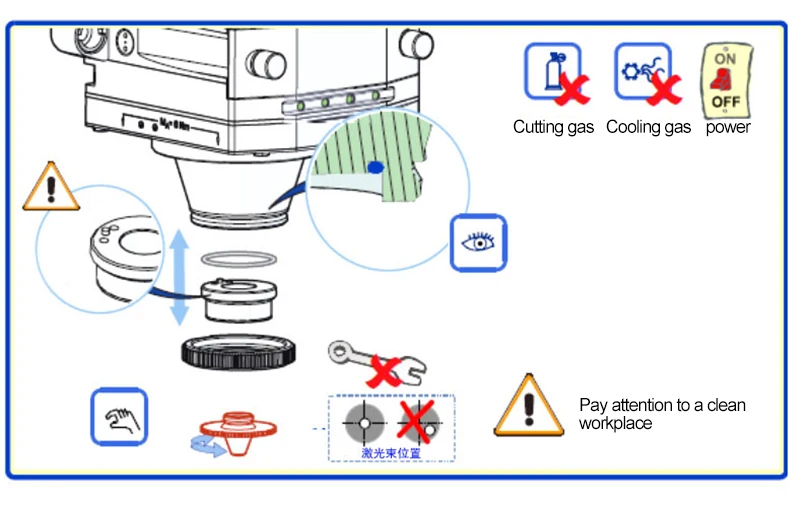

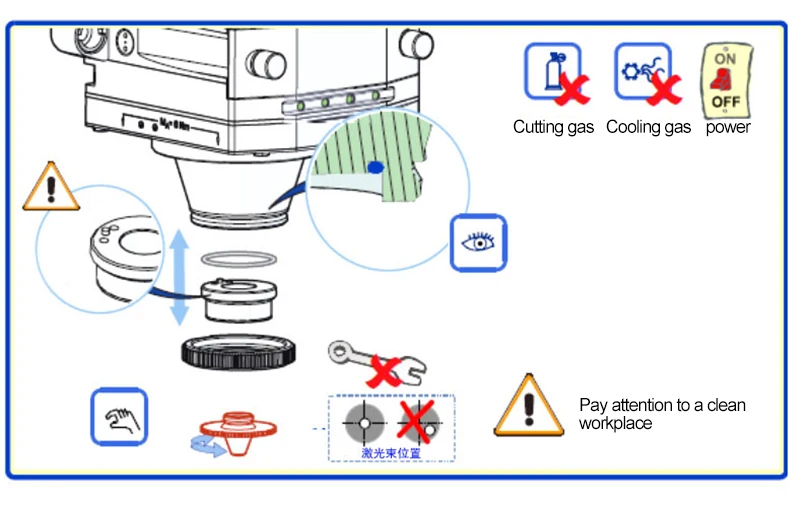

Adjust the correct position of the nozzle of the laser cutting machine. Check whether the laser is in the center of the nozzle every time the sheet is cut. If the focused light is not in the center of the nozzle, adjust the coaxiality Commonly used coaxiality adjustment steps in production are as follows: (1) Stick a sticker on the end surface of the nozzle of the laser cutting machine (2) Use 10-20 watts of power to manually punch holes (laser shots) and observe the phenomenon, and then take out the white sticker, taking care not to rotate its relative position. (3) When the nozzle position is too far from the laser center, the center point cannot be printed. (4) Try to print the center point. When the center point is large and small, please pay attention to whether the conditions are consistent and whether the focusing lens is loose. When the center point is not in the center of the nozzle of the laser cutting machine, the adjustment screw can be adjusted repeatedly until the process requirements are met.

1. When cutting thin plates (below 3mm): Generally, the aperture of the nozzle is in the range of 0.8 to 1.5mm, and the small nozzle aperture has a faster flow rate and will form a good cross section. If a larger nozzle aperture is selected, the flow rate is slower, and slag will form on the back of the sheet section. 2. When cutting medium thickness (3mm-10mm) range: 1.5mm-3.0mm aperture nozzles are generally selected. Smaller nozzles have a faster flow rate, but insufficient flow will cause insufficient combustion, and larger nozzles have a slow flow rate. Slag will form. 3. When cutting thick plates (greater than 10mm): 2.5mm 5.0mm aperture is generally selected. Thick plates have higher requirements for air flow, so larger apertures are required.

T2 level copper

Using T2 grade red copper material, it has excellent electrical conductivity, thermal conductivity, corrosion resistance and processing performance; it contains less impurities that reduce electrical conductivity and thermal conductivity.

The difference between T2 and T3

In this standard, the commonly used pure copper is divided into 1, 2, and 3 models according to the amount of impurities contained. T1: The total amount of impurities is not more than 0.05% T2: The impurities are not more than 0.1% T3 : That is, the total amount of impurities is not more than 0.3%

High speed cutting and high temperature resistance Cutting thick plates without pressure

High temperature resistance, less anti-slag, high processing precision, fast cutting speed

English

English